Advanced Automatic Packaging Line for 216.5L Drums and IBC Containers

Key Features

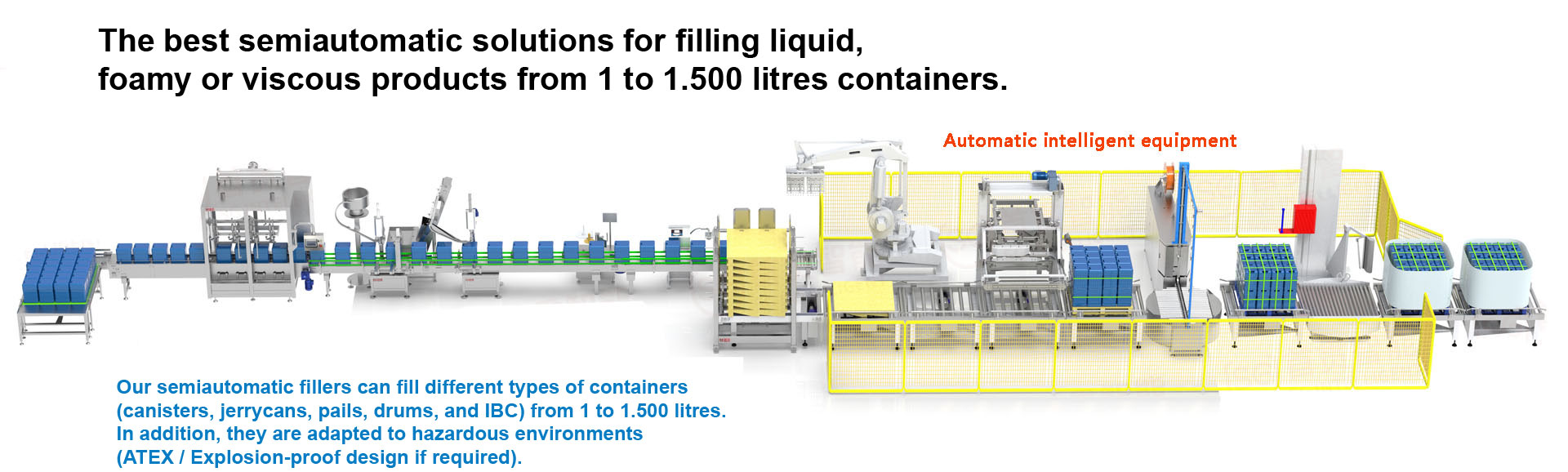

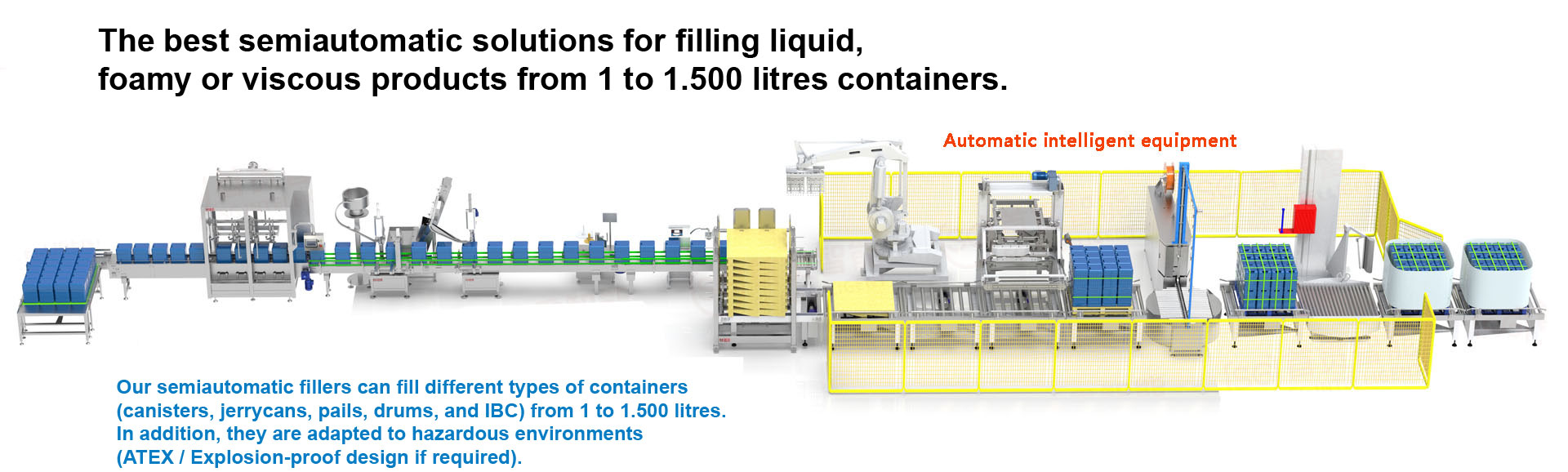

IBC barrel fully automatic filling line, expertly crafted for seamless 1000L IBC filling

Efficient container loading, with user-friendly manual assisted lid operations, and more

Streamlined automation of barrel supply, precise positioning, meticulous filling, and accurate weighing and measuring

The process is meticulously completed.

Operational Excellence Guide

During operation, simply install the empty barrel on the pipeline; it will automatically cease, and the

Innovative nozzle device positions the empty barrel precisely below the nozzle; the nozzle valve gently lowers into the

Once in the barrel mouth, the empty barrel is tared automatically, determining specific gravity with precision at dual speeds.

The spray valve smoothly connects outside the barrel, moves into the full barrel pipeline, reaching the capping station.

The piping machine halts, the cap is manually placed, the capping machine seals it, completing the weight process.

Advanced Touch Screen PLC Control

Equipped with a cutting-edge touch screen, PLC, C3 level load cell, and high-precision dual 6-bit weighing controller, sampling at 128 times/second. The frequency converter ensures top-tier filling quality and precision.

Efficient Pneumatic Filling

Utilizes computer-based weighing and submersible filling technology, complemented by frequency-conversion three-speed adjustment. The filling volume is easily set and features a gap compensation function for effortless operation.

-

Fully Automatic Nutrient Solution Barrel Subsurface Filling Machine for 1-30L[2025-04-06]

-

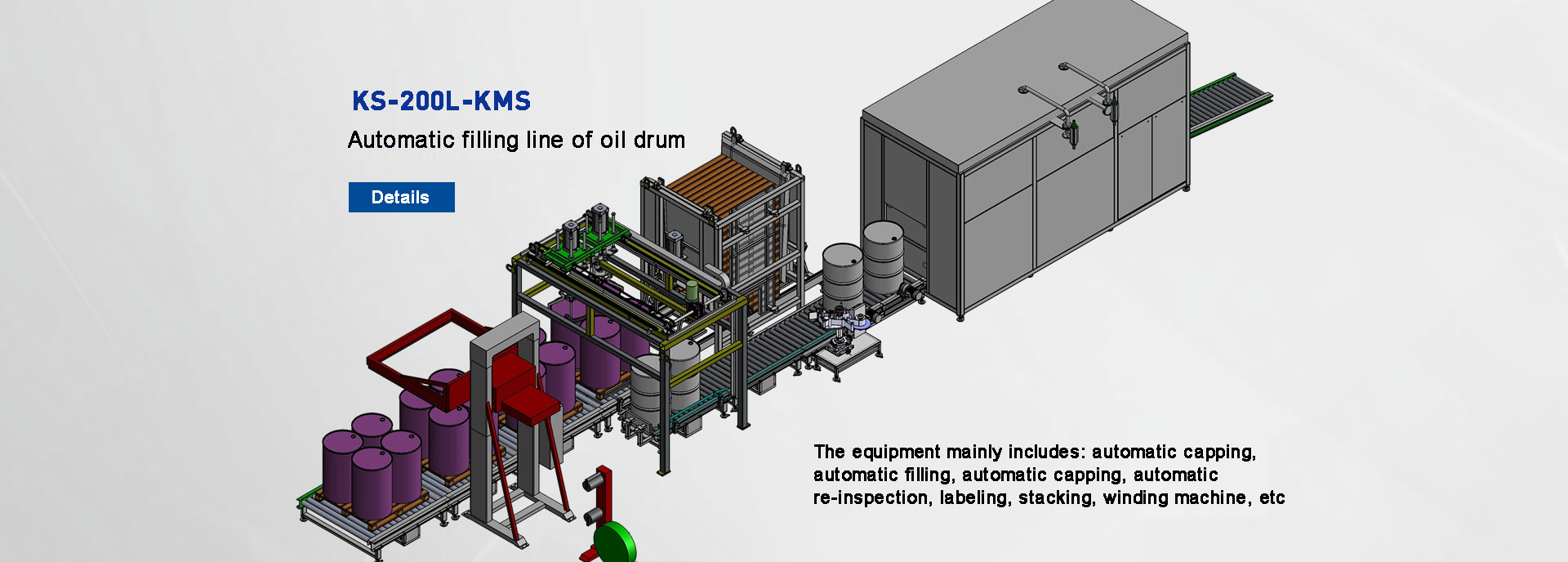

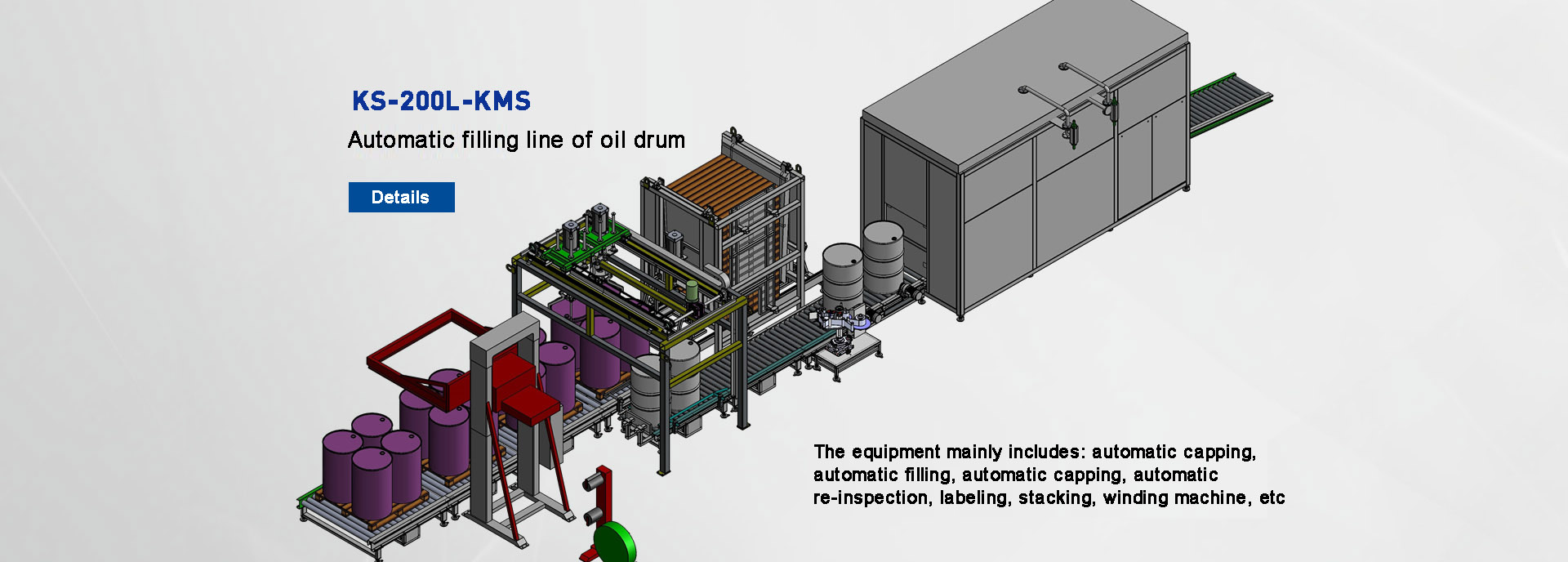

Automatic 200kg Engine Oil Drum Weighing Filling Machine[2025-04-16]

-

Acid Resin Dye Ink Methanol Lubricant Oil Drum Filling Machine[2025-04-18]

-

Small Semi-Auto Bottle Honey Juice Chili Sauce Filling Automatic Double-Head[2025-05-28]