200L Auto Caustic Paint Drum Large Capacity Paints Filling Line

2025-04-03 09:49:30

glzon

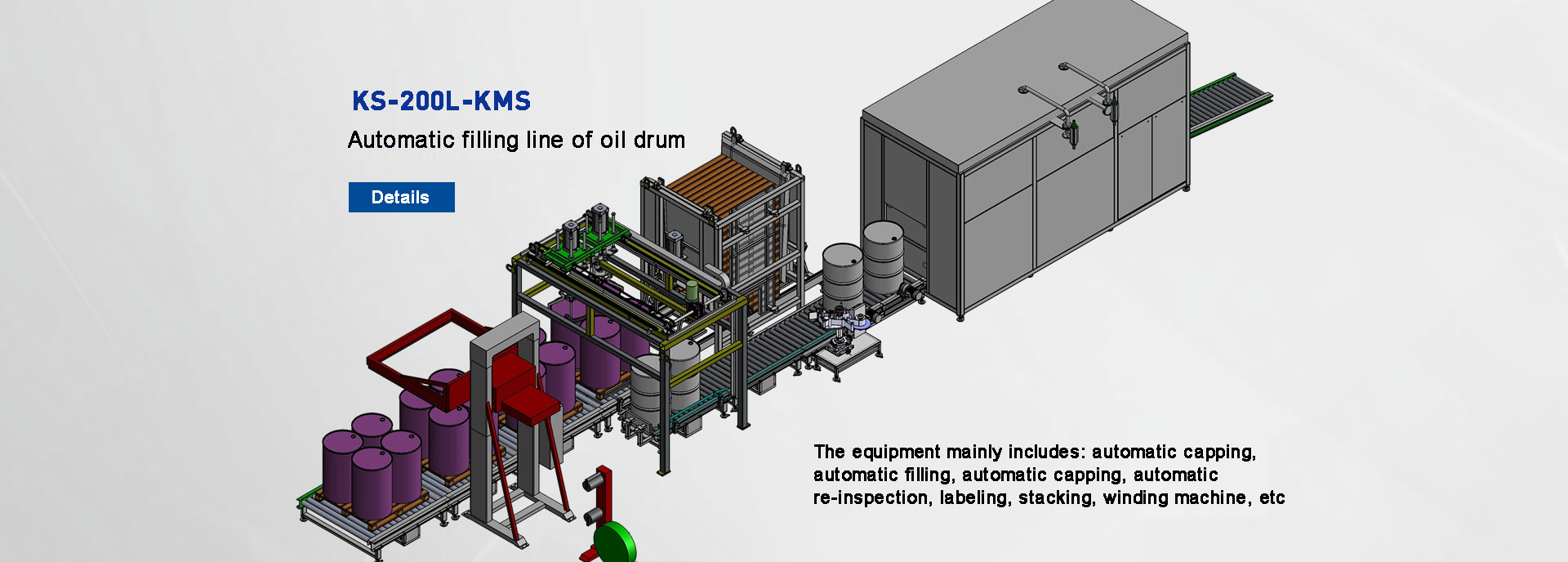

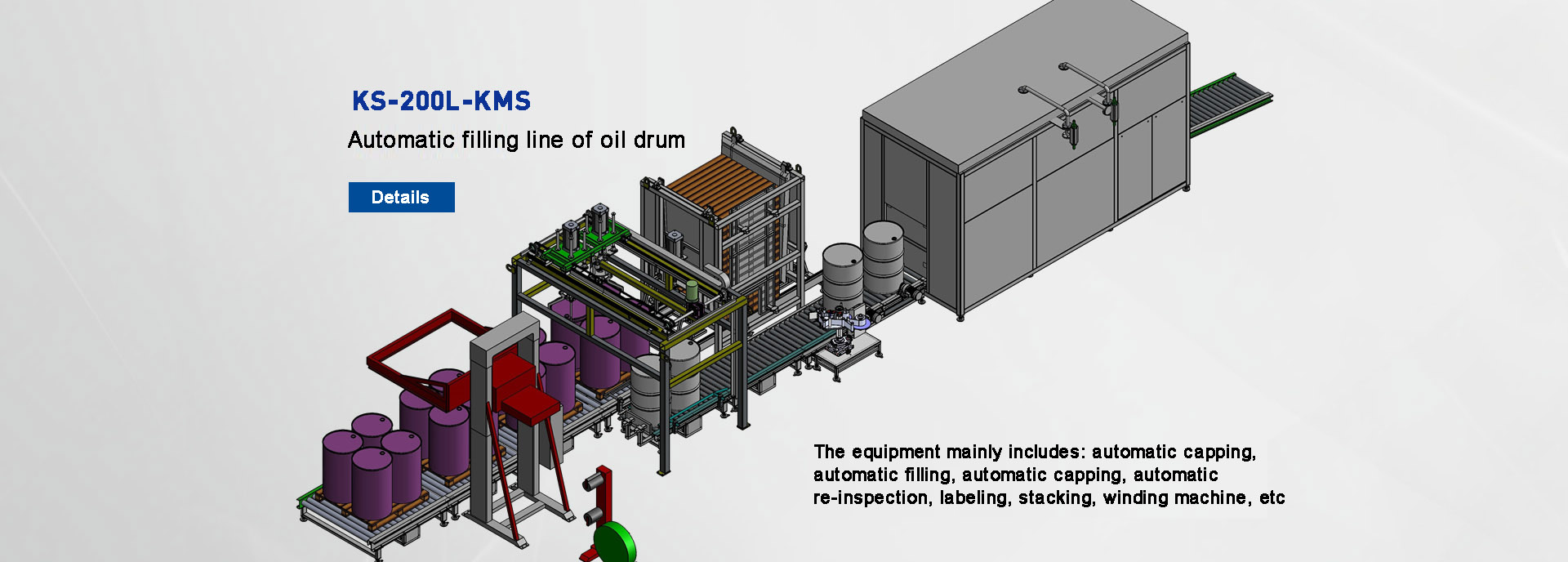

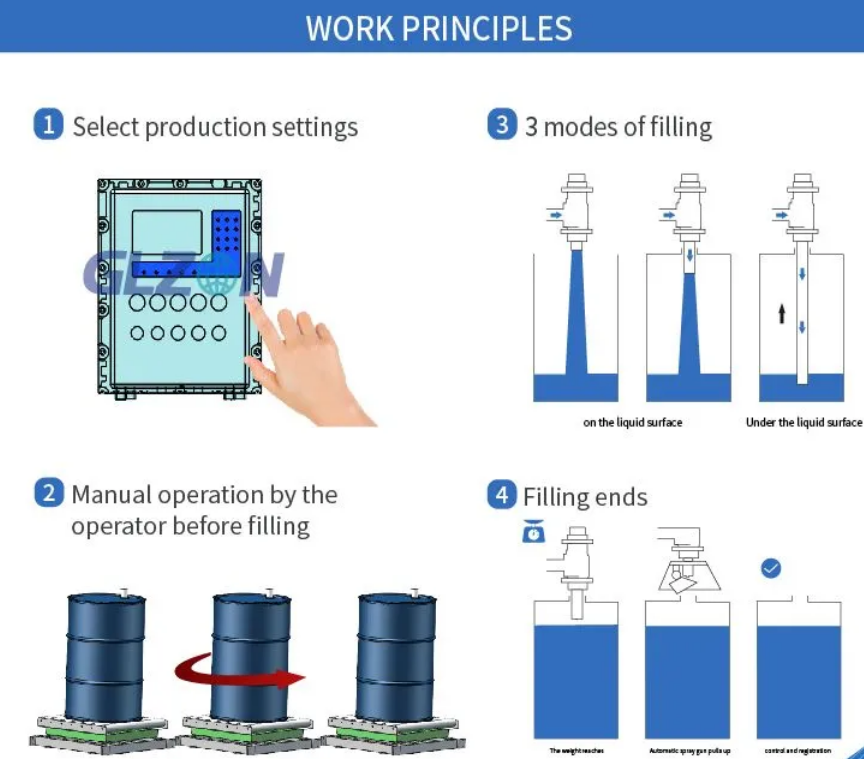

Main structure and working principle

1.Computer quantitative filling machine has feeding system, weighing system frame pneumatic control control system without power raceway and so on.

2.Feeding mode: the requirement of continuous and stable feeding (feeding pump pressurized feeding) feeding mechanism by solenoid valve through the cylinder to perform fast and slow feeding.

3.Filling method: ordinary conventional filling and lifting and diving filling (according to the needs of the order to choose).

4.The weighing platform is equipped with unpowered roller and frame support and filling system pneumatic control system: control fast and slow feeding valve in the process of using the weighing platform is not allowed to be subjected to additional external forces.

2.Feeding mode: the requirement of continuous and stable feeding (feeding pump pressurized feeding) feeding mechanism by solenoid valve through the cylinder to perform fast and slow feeding.

3.Filling method: ordinary conventional filling and lifting and diving filling (according to the needs of the order to choose).

4.The weighing platform is equipped with unpowered roller and frame support and filling system pneumatic control system: control fast and slow feeding valve in the process of using the weighing platform is not allowed to be subjected to additional external forces.

How to operate

1.During operation, as long as the empty barrel is installed on the empty barrel pipeline line, it will automatically stop and the

The nozzle device automatically places the empty barrel directly below the nozzle of the nozzle.

2.After entering the barrel mouth, the empty barrel is automatically tared, and then the specific gravity is determined accurately at two speeds.

3.The spray valve automatically connects to the outside of the barrel, enters the full barrel pipeline, and reaches the capping position.

4.The piping machine stops, the cap is placed manually, the capping machine is pulled down to cap, and the weight is completed.

The nozzle device automatically places the empty barrel directly below the nozzle of the nozzle.

2.After entering the barrel mouth, the empty barrel is automatically tared, and then the specific gravity is determined accurately at two speeds.

3.The spray valve automatically connects to the outside of the barrel, enters the full barrel pipeline, and reaches the capping position.

4.The piping machine stops, the cap is placed manually, the capping machine is pulled down to cap, and the weight is completed.

-

Industrial 200L Gel Dosing Machine - Precision Silicone & Lubricant Filling with Flow Control[2025-04-30]

-

Semi-Automatic Chemical Solution Large Capacity Drum Weighing Filling Machine for 200L[2025-05-10]

-

Small Semi-Auto Bottle Honey Juice Chili Sauce Filling Large Capacity Liquid[2025-04-12]

-

Four-Head Corrosive Liquid Filling Line for Filling 200L Drum Detergent[2025-04-02]