Automatic 200L Chemical Cream Shampoo Filling Machine High Precision Liquid Filling Equipment

Automatic 200L Chemical, Cream, and Shampoo Filling Machine

High-Precision Liquid Filling Equipment for Industrial and Bulk Applications

Overview

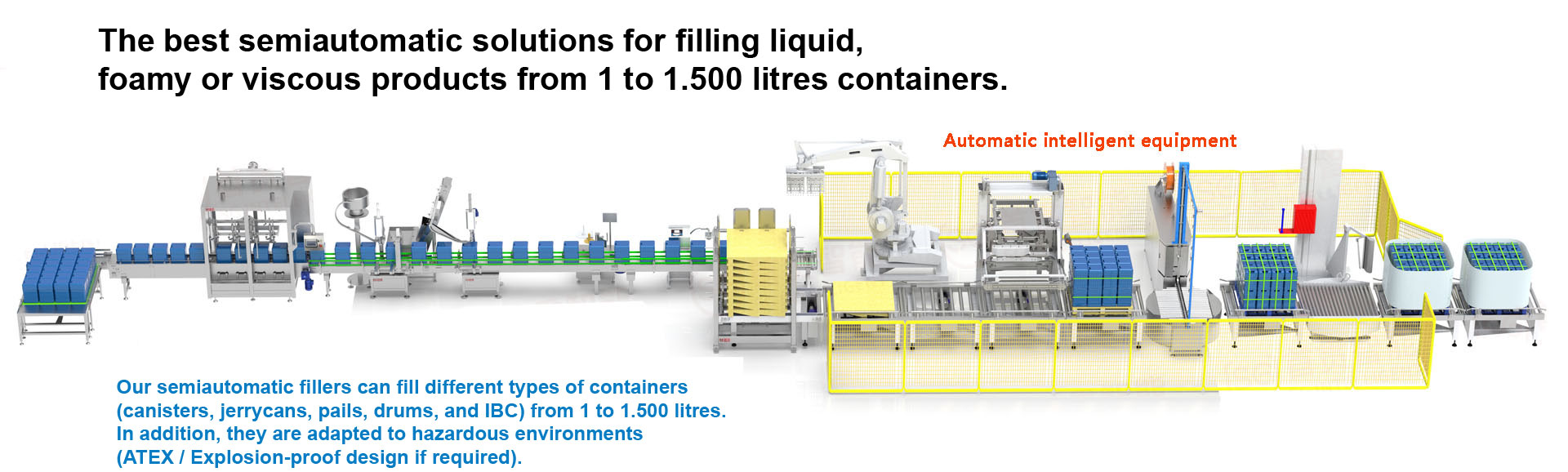

The Automatic 200L Filling Machine is designed for precise, efficient filling of liquids, creams, and pastes into large containers (e.g., 200L drums, IBC totes). It’s ideal for industries like chemicals, pharmaceuticals, food & beverage, and personal care (e.g., shampoo, lotions). With advanced automation, high accuracy, and safety features, this machine meets the demands of bulk filling operations.

Key Features

High Precision & Accuracy

Weighing System: Integrated load cells ensure ±0.1% accuracy in fill volume (customizable for higher precision).

Flow Control: Adjustable flow rates for thin liquids (e.g., chemicals) to viscous creams and pastes.

Automated Operation

PLC Touchscreen Control: User-friendly HMI interface for recipe management, batch tracking, and parameter adjustments.

Automatic Container Handling: Integrated conveyor systems or robotic arms for seamless container positioning.

Versatility & Customization

Compatibility: Suits 200L drums, IBC totes, and other large containers (customizable for different sizes).

Material Options: Stainless steel (304/316L) for corrosive products; optional PTFE or Hastelloy coatings for aggressive chemicals.

Nitrogen Blanketing: Prevents foaming or oxidation in sensitive liquids (e.g., volatile chemicals).

Safety & Compliance

ATEX/IECEx Certification: Safe for hazardous environments (Zone 2/22).

Static Grounding & Dust Explosion Protection: Ensures safe operation with flammable liquids.

Emergency Stop & Interlocks: Prevents accidents during operation.

Ease of Maintenance

Modular Design: Quick access to components for cleaning and servicing.

Self-Cleaning Nozzles: Purge and clean cycles reduce downtime between product changes.

Technical Specifications

Filling Capacity: 200 liters per container (customizable for other sizes).

Filling Speed: Up to 60–120 containers/hour (depends on viscosity and nozzle type).

Accuracy: ±0.1% of target volume.

Power: 220V/50Hz or 380V/60Hz (energy-efficient servo motors).

Materials: Stainless steel (304/316L), PTFE, or Hastelloy (for aggressive chemicals).

Certifications: CE, ISO, ATEX, UL, and more.

Applications

Chemicals: Acids, bases, solvents, and industrial fluids.

Personal Care: Shampoo, lotions, creams, and gels.

Food & Beverage: Edible oils, sauces, and non-corrosive liquids (with food-grade materials).

Pharmaceuticals: Non-hazardous liquid medications and formulations.

Operation Steps

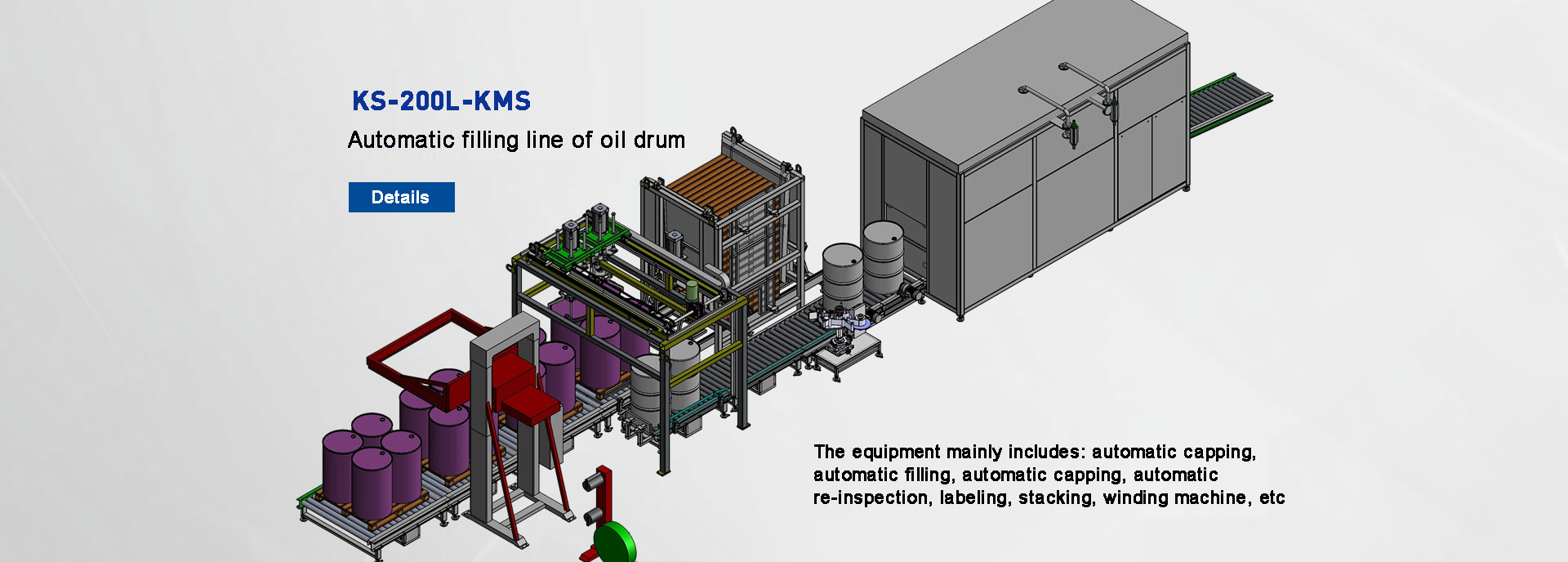

Container Placement: Automated conveyor positions the 200L container under the filling nozzle.

Pre-Filling: Nitrogen blanketing (if enabled) purges oxygen from the container.

Automatic Filling: The system dispenses the liquid at a controlled rate, monitored by load cells.

Weighing & Cutoff: Filling stops once the target weight is reached.

Post-Filling: Nozzle retracts, and the container moves to capping or sealing stations.

Optional Features

Capping Systems: Automatic twist-off or screw capping for sealed containers.

Labeling Machines: Integrated or standalone labelers for batch numbers, expiry dates, and barcodes.

Remote Monitoring: IoT connectivity for real-time data tracking and predictive maintenance.

Vacuum Filtration: For removing impurities from liquids during filling.

Benefits

Precision & Consistency: Eliminates overfilling or underfilling, reducing material costs and waste.

Flexibility: Handles a wide range of viscosities and container types with minimal setup changes.

Labor Efficiency: Automated processes reduce manual work and errors.

Safety: Spill-proof design and compliance with hazardous area standards protect operators and equipment.

Low Maintenance: Durable materials and self-cleaning features minimize downtime.

Why Choose This Machine?

The 200L Automatic Filling Machine offers a reliable, high-precision solution for industrial liquid filling. Its robust design, advanced automation, and customizable features make it ideal for chemical, pharmaceutical, and personal care manufacturers. Whether you need manual or fully automated systems, this machine delivers efficiency, accuracy, and safety.

Contact us today for a tailored solution!

Immediate Order:

Website: http://m.360banjia.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Multi-Purpose Checkweighing Filling Machine for Filling 220L Sauce/Coupling Agent[2025-07-04]

-

Dual-Speed packaging machine Equipment Co., Ltd.[2025-06-28]

-

Powder Weighing packaging machine Arm Type packaging machine[2025-06-28]

-

200L Fully Automatic High Temperature Bitumen/Asphalt Filling Machine[2025-04-15]