High-Speed Semi-Automatic Liquid Pail Filling Machine for Paint 3

High-Speed Semi-Automatic Liquid Pail Filling Machine for Paint

Key Features

High-Speed Filling

Rapid Cycle Times: Capable of filling pails (5L to 30L) at speeds of up to 600 pails per hour, depending on the model and viscosity of the paint.

Semi-Automatic Operation: Operator-controlled start/stop with automated filling cycles for efficiency.

Versatility for Paints & Coatings

Viscosity Handling: Designed for medium to high-viscosity fluids (e.g., water-based, solvent-based, or oil-based paints).

Adjustable Volume: Preset fill volumes for different pail sizes (e.g., 1L, 5L, 20L, etc.).

Precision & Accuracy

Volumetric or Gravimetric Filling: Optional weight-based filling (load cells) for ±0.2% accuracy, ensuring consistent fill levels.

No-Drip Nozzles: Self-closing nozzles prevent drips and spills, maintaining cleanliness and reducing waste.

Semi-Automatic Controls

Foot Pedal or Pull-Down Lever: Ergonomic controls allow operators to start/stop filling cycles hands-free.

Digital Display: Monitors fill volumes, batch counts, and error alerts for easy operation.

Safety & Containment

Static Grounding Clamp: Ensures safe handling of flammable or combustible materials like solvent-based paints.

Fume Extraction Arm: Directs fumes away from the operator (optional accessory).

Overfill Protection: Automatic shutoff to prevent overfilling and spillage.

Durable Construction

Stainless Steel or Corrosion-Resistant Materials: Suitable for aggressive paints and chemicals.

Chemical-Resistant Hoses & Seals: Long-lasting components designed for paint compatibility.

Customization Options

Multiple Filling Heads: Add a second nozzle for dual-pail filling to double productivity.

Nitrogen Blanketing: Purge pails with inert gas to prevent skinning or contamination (ideal for waterborne paints).

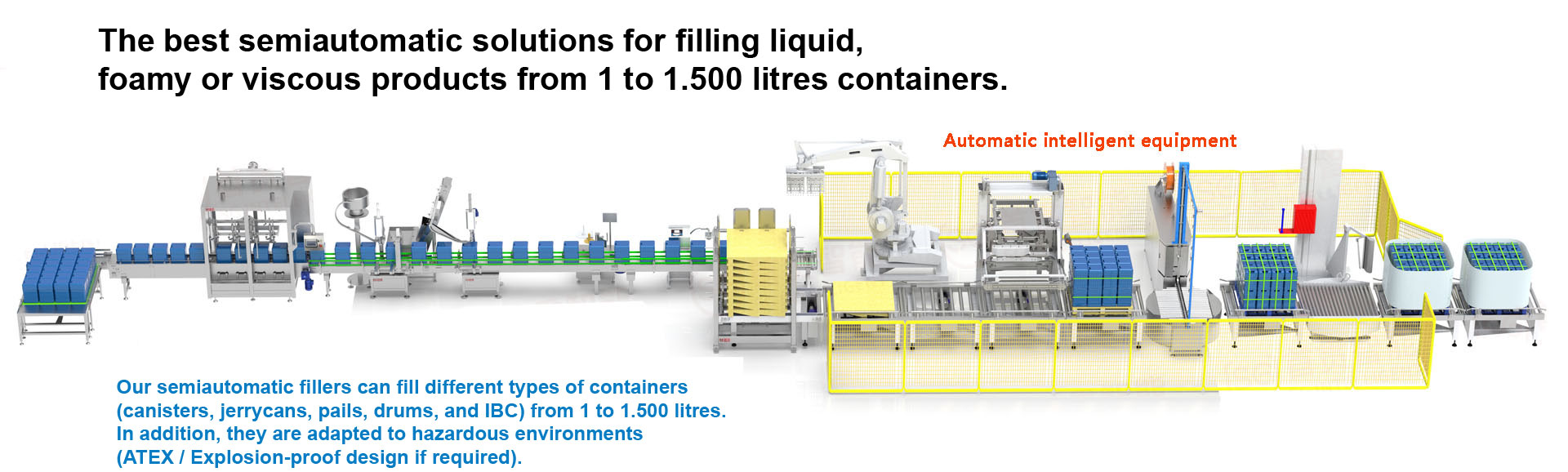

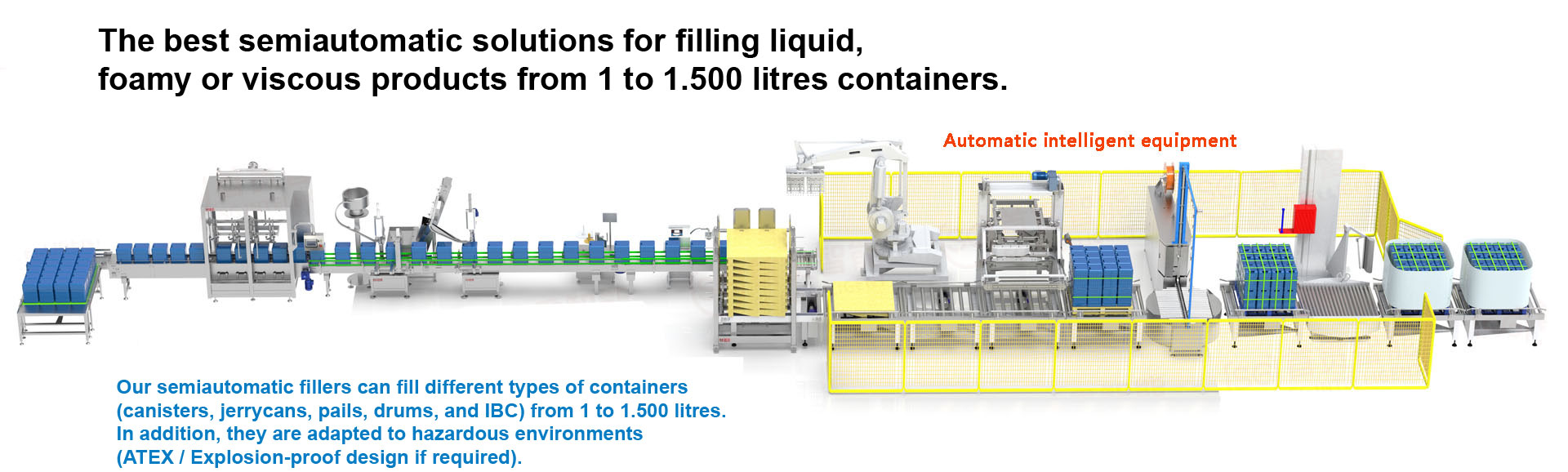

Conveyor Integration: Automate pail movement with an optional conveyor system.

Applications

Paint Manufacturing: Filling water-based, solvent-based, or oil-based paints into pails, cans, or drums.

Coatings & Varnishes: High-viscosity coatings, wood stains, and varnishes.

Industrial Fluids: Adhesives, sealants, and specialty chemicals requiring precise filling.

Food-Grade Applications: Edible oils, sauces, or food-safe coatings (with appropriate certifications).

How It Works

Pail Placement: Operator positions the pail under the fill nozzle.

Start Filling: Activate the machine via foot pedal or pull-down lever.

Automated Dispensing: The pump dispenses the precise volume of paint into the pail.

Shutoff & Sealing: The nozzle automatically closes once the target volume is reached, preventing drips.

Repeat: Continue with additional pails or adjust settings for different products.

Benefits

Efficiency: High-speed filling reduces labor costs and increases productivity.

Accuracy: Consistent fill volumes minimize product waste and ensure quality control.

Safety: No-spill design, static grounding, and fume extraction protect operators and the environment.

Flexibility: Easy adjustments for different pail sizes, paint types, and fill volumes.

Low Maintenance: Robust construction and simple design minimize downtime and upkeep.

Optional Accessories

Conveyor System: Automates pail movement for continuous filling.

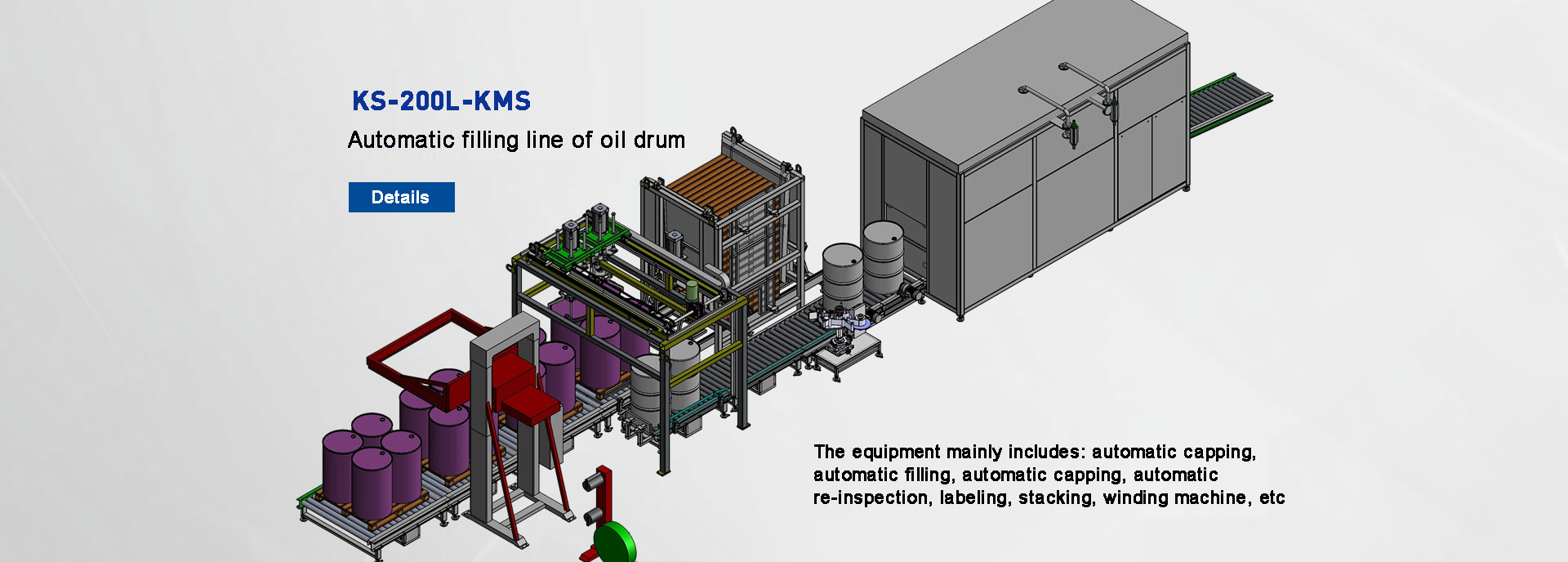

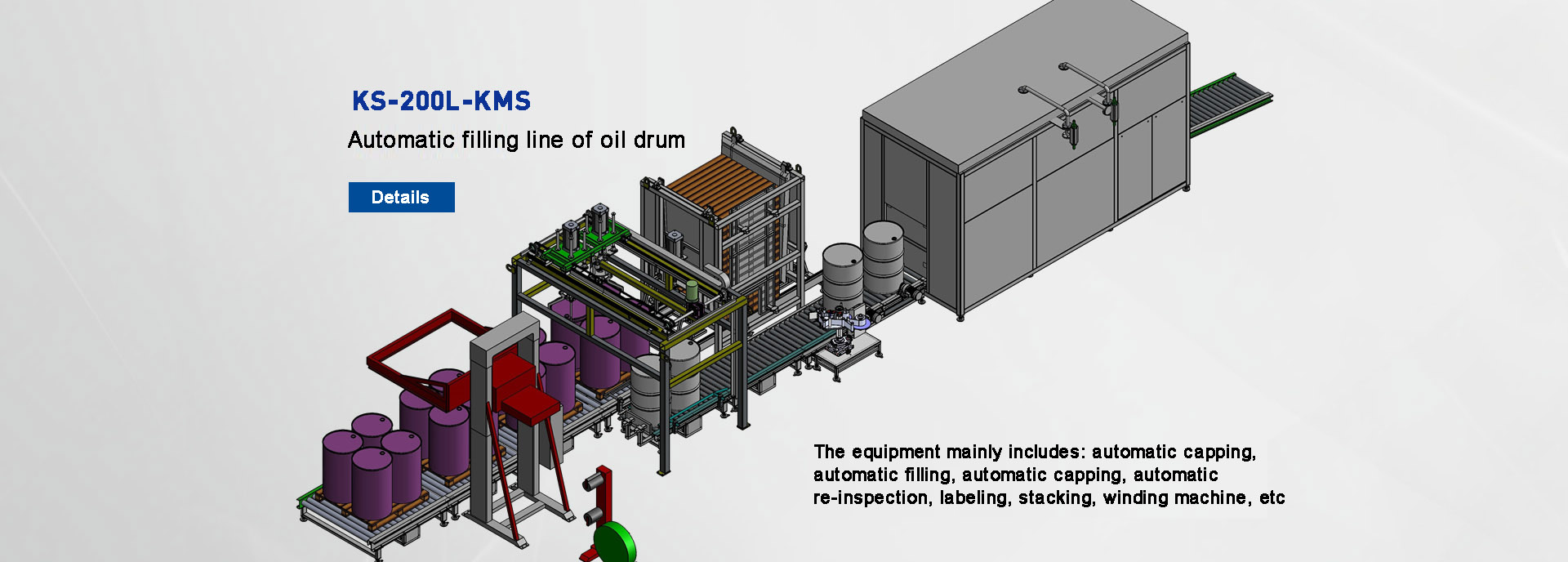

Capping Machine: Seals lids or caps after filling (e.g., tamper-evident caps).

Labeling System: Apply batch numbers, expiration dates, or barcodes for traceability.

HEPA Filtration: Add-on for capturing fine fumes or particles during filling.

Why Choose This Machine?

This High-Speed Semi-Automatic Pail Filler is ideal for:

Paint Manufacturers: Efficiently filling pails of water-based, solvent-based, or oil-based paints.

Contract Packers: Versatile filling for diverse client products (paints, adhesives, etc.).

Warehouses & Distributors: Repacking bulk paints into smaller containers for distribution.

Small to Medium Enterprises: Cost-effective solution with semi-automation for scalability.

Ideal For

Paint Production Lines: High-volume filling of pails, drums, or IBC totes.

Automotive & Industrial Workshops: Filling paint pails for touch-up, refinishing, or custom blends.

Food & Pharmaceutical Industries: Food-grade or pharma-compliant filling (with appropriate certifications).

The High-Speed Semi-Automatic Pail Filling Machine offers a reliable, efficient solution for filling paints and other viscous liquids. Its precision, safety features, and customization options make it perfect for industrial paint manufacturers, contract packers, and distributors.

Immediate Order:

Website: http://m.360banjia.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Fully Automatic 1 Nozzle Automatic Checkweighing Automotive Ink & Chemical Raw Material Liquid 30L Can Filling Machine[2025-04-30]

-

GZM-25H Automatic Pail Filler with a Crown Lid, Touch Screen, Explosion-proof, for Chemical Solvents Chemical Plant_2[2025-05-05]

-

Semi-Automatic Disinfectant Pails Metering and Filling Machine for 25L[2025-05-17]

-

Precision 200L Drum Filler a Reliable Efficient Machine for High-Accuracy Lube Oil Drum Filling 200-Liter.[2025-05-09]