IBC Tote Filling Machine for Bulk Liquid Packaging

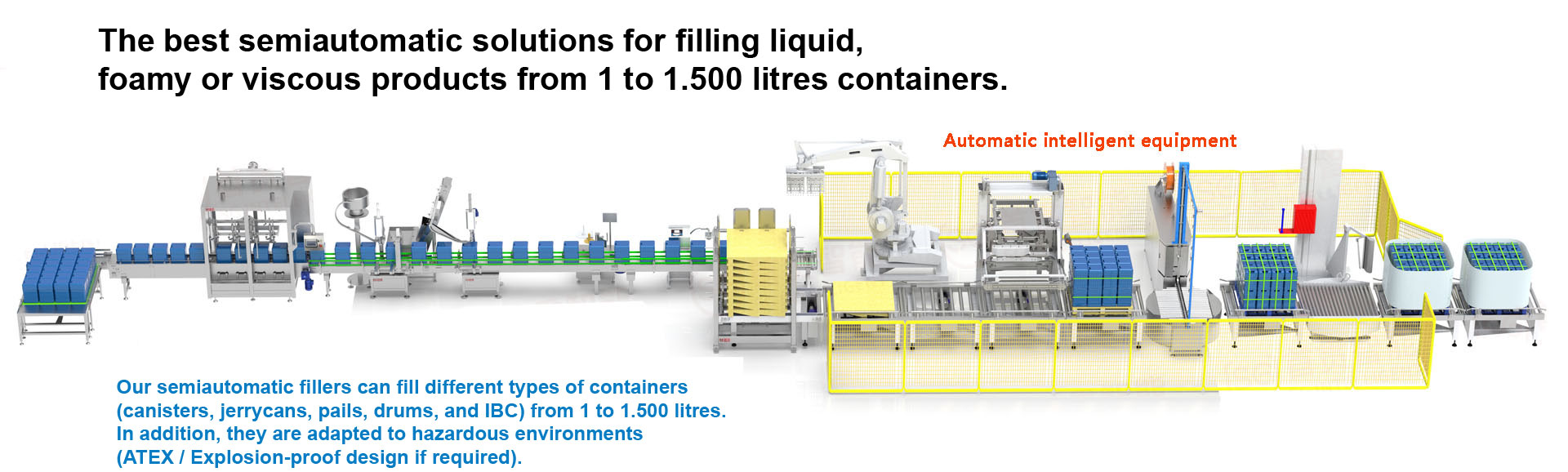

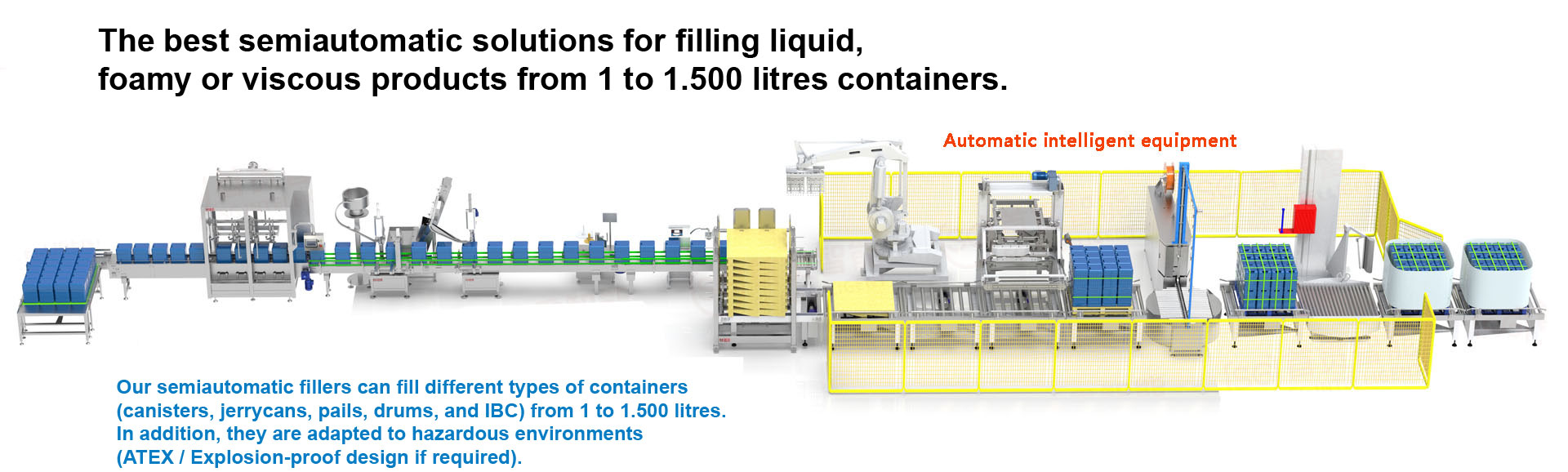

An IBC Tote Filling Machine is a specialized system designed for efficient, accurate, and safe bulk liquid packaging into Intermediate Bulk Containers (IBC Totes). These machines are essential for industries that handle large volumes of liquids, such as chemicals, food products, pharmaceuticals, oils, and more. Below is a comprehensive overview of IBC Tote filling machines, their features, applications, and benefits.

Overview:

An IBC Tote Filling Machine automates the process of filling large IBC totes (typically 1,000 to 3,000 liters) with liquids. These machines ensure precision, reduce labor costs, minimize spills, and enhance safety in bulk liquid handling operations. They are designed to meet stringent industry standards for accuracy, hygiene, and compatibility with hazardous or corrosive materials.

Key Features:

High-Capacity Filling:

Designed for filling IBC totes with capacities ranging from 1,000 to 3,000 liters (or more).

Suitable for both low-viscosity (e.g., water, juices) and high-viscosity liquids (e.g., syrups, oils).

Precision Filling:

Advanced flow meters and level sensors ensure ±0.5% accuracy in fill volume.

Adjustable filling speeds to prevent splashing or frothing.

Automated Operation:

Fully automated filling process with minimal operator intervention.

Optional automatic container recognition (e.g., RFID or barcode scanning) for hands-free operation.

Corrosion-Resistant Construction:

Made from 316L stainless steel or Hastelloy for compatibility with corrosive chemicals.

Food-grade gaskets and seals for applications in the food and pharmaceutical industries.

Touchscreen Interface:

User-friendly HMI (Human-Machine Interface) for easy programming and operation.

Store multiple product profiles for different liquids and fill volumes.

Drip-Free Nozzles:

High-precision nozzles prevent dripping and spillage during filling.

Optional anti-foam design for viscous or frothy liquids.

Safety Features:

Overfill protection to prevent spillage and product waste.

Emergency stop button and safety interlocks for operator protection.

Grounding cables and static-dissipative materials to prevent sparks in hazardous environments.

Level Sensors:

Integrated level sensors (e.g., radar, ultrasonic) ensure precise fill levels and prevent overfilling.

Options for weight-based filling using integrated load cells.

Cleaning and Maintenance:

CIP (Clean-In-Place) capability for easy cleaning and sanitization.

Removable components and smooth surfaces reduce contamination risks.

Modular Design:

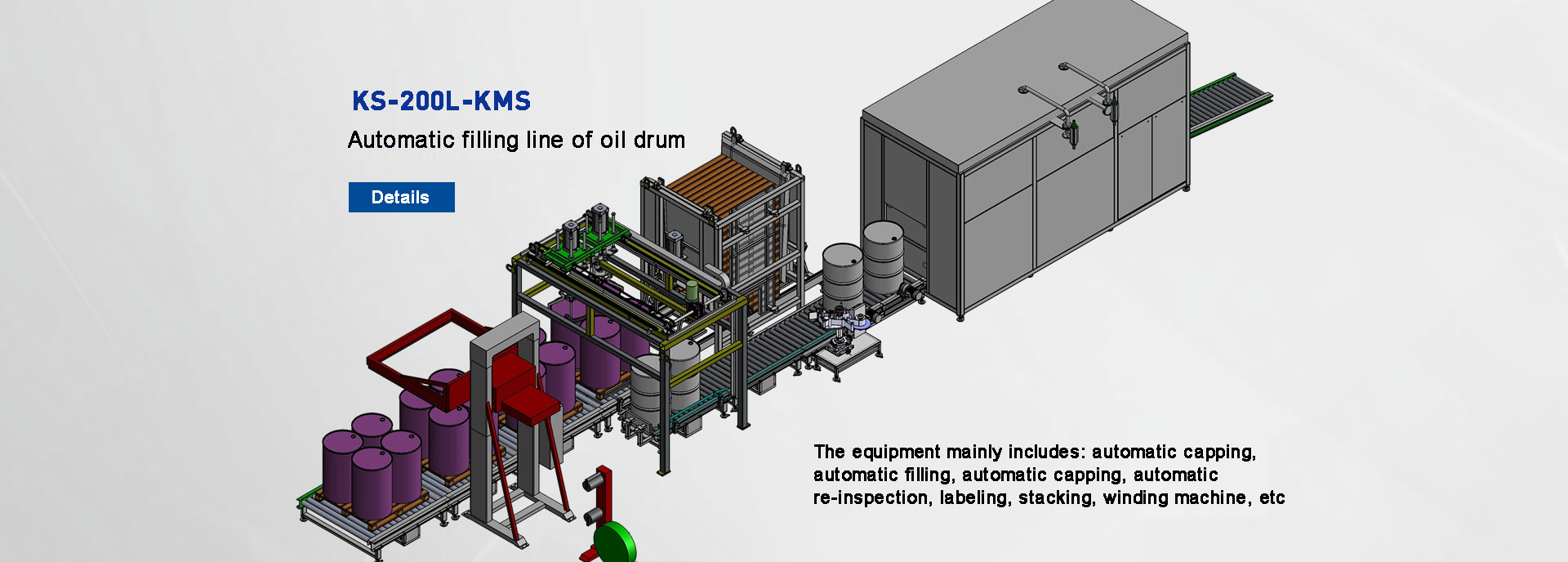

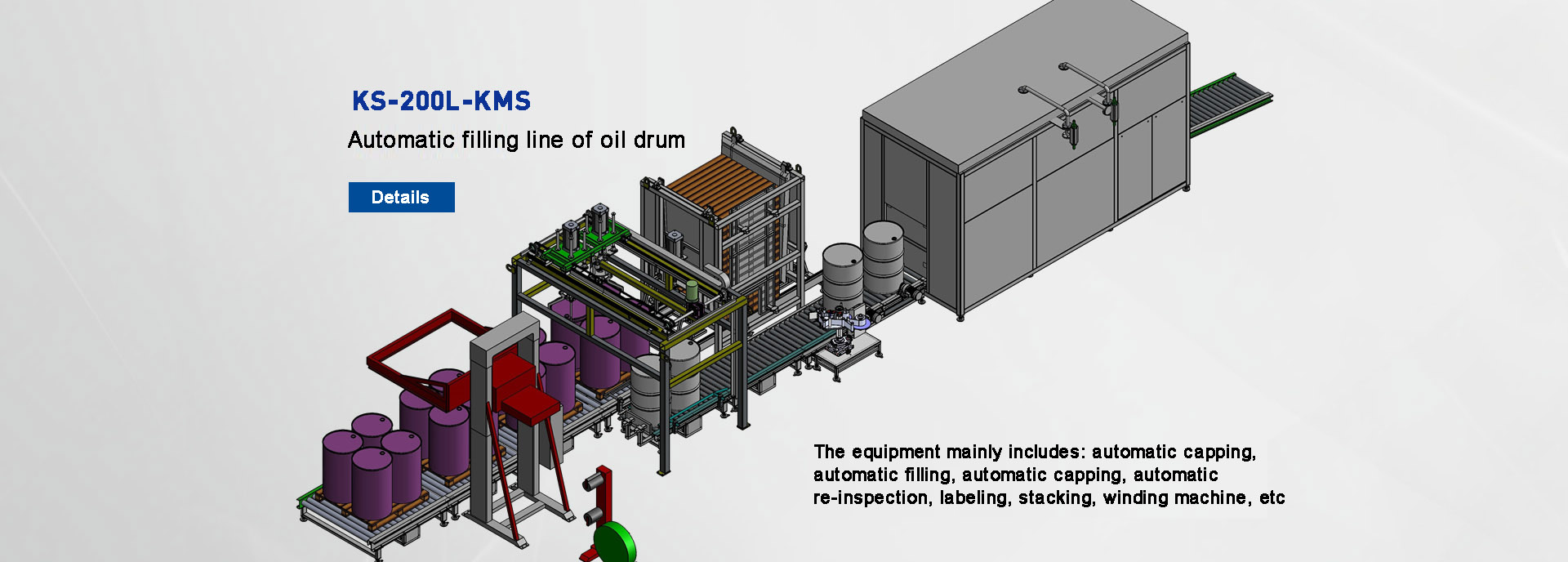

Conveyor systems for automated IBC tote transport.

Data logging for traceability and compliance.

Explosion-proof motors for hazardous environments (ATEX, CE certification).

Customizable with optional add-ons such as:

Applications:

Chemicals: Filling acids, solvents, industrial fluids, and corrosive substances.

Food & Beverage: Filling oils, sauces, juices, and other food-grade liquids.

Pharmaceuticals: Filling oral solutions, syrups, and bulk pharmaceutical ingredients.

Oils & Lubricants: Filling engine oils, hydraulic fluids, and greases.

Agriculture: Filling fertilizers, pesticides, and crop protection chemicals.

Industrial: Filling lubricants, adhesives, and specialty chemicals.

Benefits:

Efficiency:

Automates bulk filling processes, reducing labor costs and increasing throughput.

Accuracy:

±0.5% filling accuracy minimizes product giveaway and ensures consistent fill levels.

Safety:

Drip-free nozzles, overfill protection, and grounding systems reduce spills and operator risk.

Versatility:

Suitable for a wide range of liquids and IBC tote sizes, making it adaptable to various industries.

Hygiene:

CIP capability and food-grade materials ensure compliance with hygiene standards for food and pharma applications.

Cost-Effective:

Reduces product waste, labor costs, and downtime compared to manual filling methods.

Compliance:

Meets industry standards (e.g., FDA, EHEDG, NSF) and safety certifications (e.g., ATEX, CE).

Scalability:

Modular design allows for future upgrades, such as conveyor integration or data logging.

Technical Specifications (Example):

Filling Capacity: 1,000 to 3,000 liters per minute (adjustable)

Filling Accuracy: ±0.5%

Nozzle Type: Drip-free, adjustable height

Materials: 316L stainless steel (food and pharma grade), Hastelloy (optional)

Power Source: Electric (220V/50Hz or 110V/60Hz) or pneumatic (optional)

Dimensions: Compact footprint (e.g., 1500mm x 1200mm x 2000mm)

Weight: ~300 kg (depending on configuration)

Safety Certification: CE, FDA, EHEDG, NSF, ATEX (optional)

Optional Add-Ons:

Conveyor System: Automated transport of IBC totes for continuous filling.

RFID/Barcode Scanners: For automatic container recognition and tracking.

Data Logging: USB or Ethernet connectivity for recording fill data and integration with MES/ERP systems.

Weight-Based Filling: Integrated load cells for gravity-based filling and weight verification.

Explosion-Proof Motors: For hazardous environments (ATEX certification).

Anti-Foam Nozzles: For filling viscous or frothy liquids without creating bubbles.

Level Sensors: Radar or ultrasonic sensors for precise fill level control.

Conclusion:

An IBC Tote Filling Machine is a reliable, efficient, and safe solution for bulk liquid packaging in industries such as chemicals, food, pharmaceuticals, and more. With its automated operation, precision accuracy, and robust construction, it minimizes labor costs, reduces spills, and ensures compliance with strict industry standards. Whether you need a basic system or a fully customized solution with advanced features, an IBC Tote Filling Machine is a valuable investment for streamlining bulk liquid handling operations.

Immediate Order:

Website: http://m.360banjia.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Fully Automatic 1 Nozzle Automatic Checkweighing Automotive Ink & Chemical Raw Material Liquid 30L Can Filling Machine[2025-04-30]

-

Bucket Paint Filling Machine Semi Automatic and Automatic Paint Filling Systems 2[2025-06-07]

-

Full Automatic Glass Bottle Jar Honey Filling and Sealing Machine[2025-05-20]

-

China Small Automatic Liquid Wine Palm Manufacturing Filling[2025-05-06]