Semi-Auto Pail Weight Filling Machine for Water Injection and Drying Prevention of Paint_2

Semi-Automatic Pail Weight Filling Machine for Water Injection & Drying Prevention in Paint

Overview:

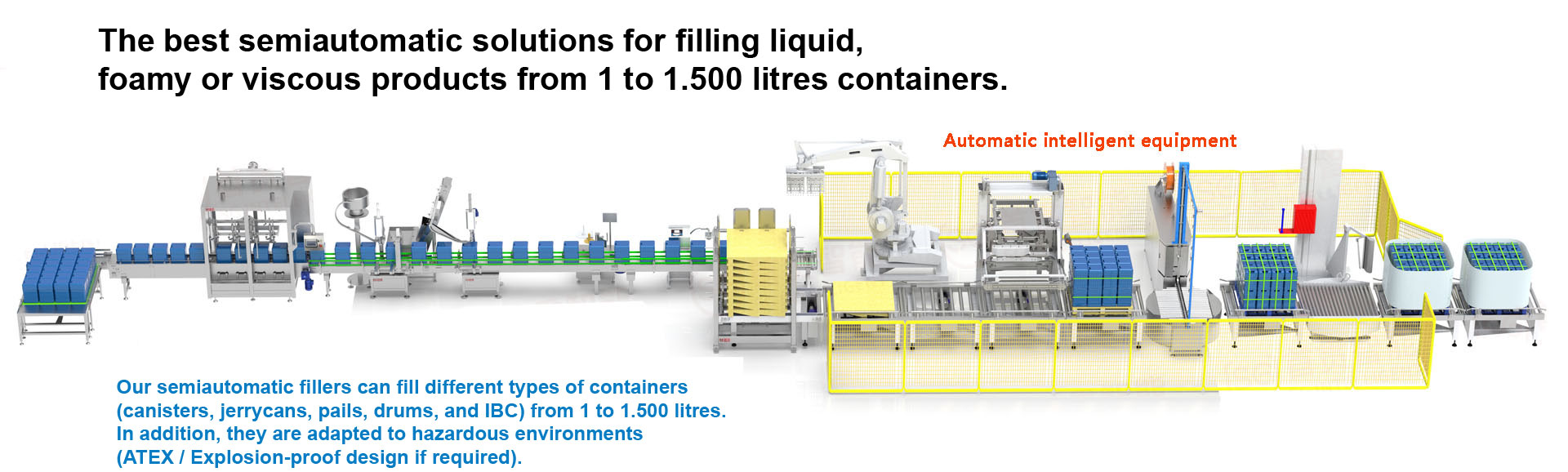

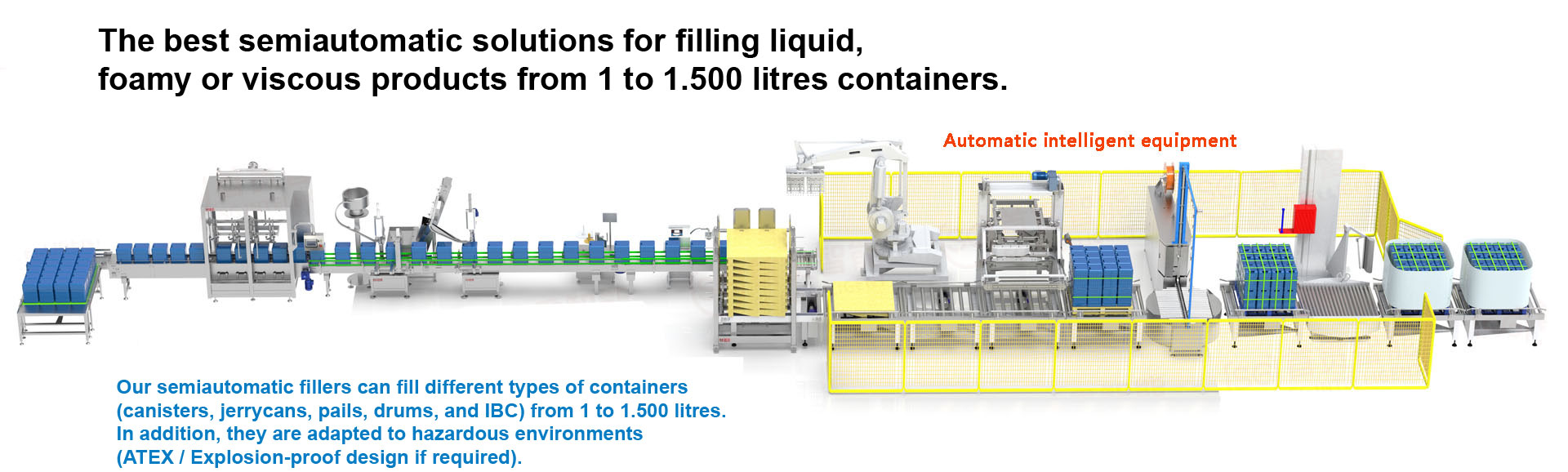

The Semi-Auto Pail Filling Machine is designed for precise, efficient filling of water into paint pails while integrating drying prevention features to maintain paint integrity. It combines weight-based accuracy, splash-free operation, and optional automation for seamless water injection into 5–25L pails.

Key Features:

Precision Filling:

Weight-Based Control: ±0.1% accuracy using load cells and HMI touchscreen calibration.

Flow Rate Adjustment: Variable speed pumps for controlled water dosing.

Anti-Splash Nozzle: Stainless steel, drip-free design to minimize contamination.

Drying Prevention Integration:

Inert Gas Blanketing (Optional): Introduces nitrogen or CO? to create a protective layer, preventing oxidation and drying.

Sealed Pail Lid: Compatible with sealed or vented lids; optional automatic capping for airtight closure.

Humidity Control: Desiccant packs or moisture-absorbing lids (optional).

Safety & Compliance:

ATEX/IECEx Certified: For safe operation in hazardous environments (paint fumes).

Static Dissipation: Conductive materials and grounding systems to prevent sparks.

Corrosion-Resistant Build: 304/316L stainless steel frame, PTFE seals, and chemical-resistant coatings.

Ease of Use:

Semi-Auto Operation: Manual pail placement with foot pedal or HMI start.

Quick Changeover: Tool-free nozzle swaps for different pail sizes (5–25L).

HMI Touchscreen: Save recipes for varying water volumes and pail types.

Cleaning & Maintenance:

CIP Compatibility: Clean-in-Place options with automated rinse cycles.

Removable Drip Tray: Stainless steel tray for easy cleanup.

Nozzle Purging: Automatic blowdown with air or solvent to prevent clogging.

Customization Options:

Heaters/Stirrers: Keep paint at optimal temperature and consistency.

Fumes Extraction: Integration with overhead arms or downdraft tables.

Barcode Scanning: Track batches and ensure traceability.

Technical Specifications:

Filling Range: 1–25 liters (adjustable in 0.1L increments).

Accuracy: ±0.1% of target weight.

Materials: 304/316L stainless steel, PTFE seals, FKM gaskets.

Safety Certification: ATEX, IECEx, CE.

Power Requirements: 220V/50Hz or 110V/60Hz (customizable).

Environment Rating: IP65 (dust and water resistant).

Operation Steps:

Pail Placement: Manually position the empty paint pail under the filling nozzle.

Start Cycle: Initiate via foot pedal or HMI touchscreen.

Water Injection: The machine fills the pail to the preset weight, stopping automatically.

Inert Gas Blanketing (If Equipped): Optional nitrogen/CO? purge to protect the paint surface.

Capping (Optional): Seal the pail with an automated capping system.

Pail Removal: Manually remove the filled pail or use an optional conveyor.

Cleanup: Nozzle purges automatically to prevent cross-contamination.

Applications:

Paint Manufacturing: Water injection into base coats, primers, or thinners.

Coatings Production: Accurate dilution of high-viscosity coatings.

Industrial Chemicals: Filling water into pails for other liquid formulations.

Benefits:

Precision & Consistency: Ensures exact water volumes to maintain paint viscosity and quality.

Drying Prevention: Inert gas blanketing and sealed lids protect paint from oxidation.

Safety: ATEX/IECEx compliance and static dissipation for hazardous environments.

Efficiency: Quick changeovers and semi-auto operation reduce labor time.

Customization: Tailored for specific pail sizes, water volumes, and drying prevention needs.

Low Maintenance: Robust design with CIP and removable components for easy cleaning.

Why Choose Us?

As a manufacturer, we specialize in custom filling solutions for paint, coatings, and chemicals. Our machines are built to balance precision, safety, and efficiency while addressing unique challenges like drying prevention. Contact us for a tailored quote or consultation!

Immediate Order:

Website: http://m.360banjia.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

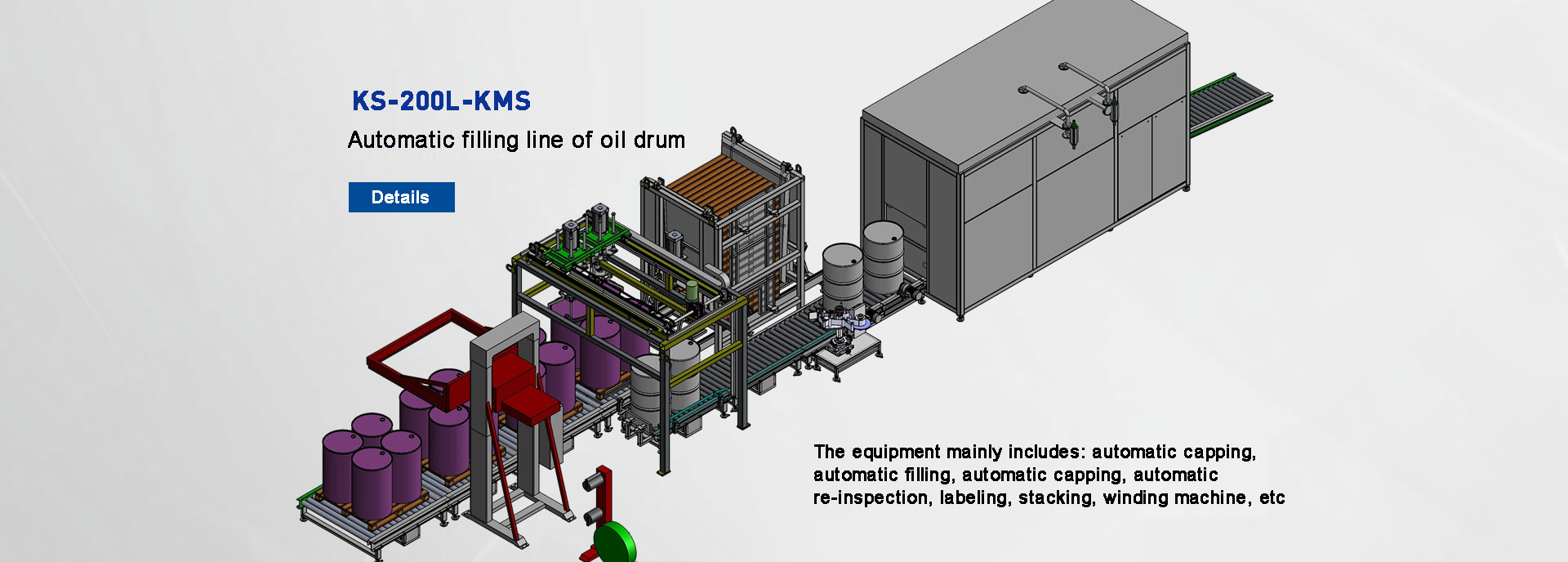

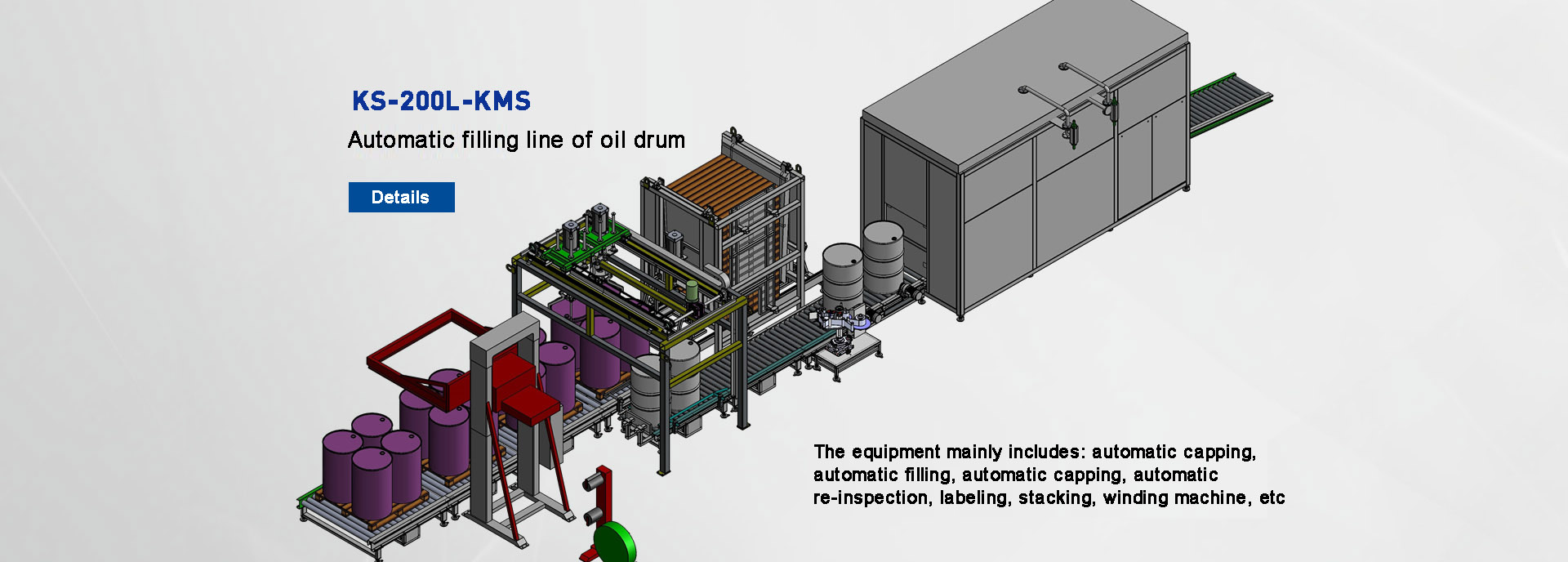

Multifunctional Filling Machine Is Suitable for Filling 200L Slurry/Emulsifiable Concentrate/Resin Drum[2025-05-13]

-

Paint & Coating Filling Machine | 18KG Manual Filling System with Automated Solutions[2025-05-16]

-

Explosion-Proof Liquid Filling Machine for Real Stone Paint in Pail Is Easy to Operate and Has a Favorable Price[2025-05-05]

-

China Small Automatic Liquid Wine Palm Manufacturing Filling[2025-04-12]