Automatic Double-head Liquid Pail Filling Machine for Engine Oil With a Crown Lid_

Automatic Double-Head Liquid Pail Filling Machine for Engine Oil with a Crown Lid

Overview

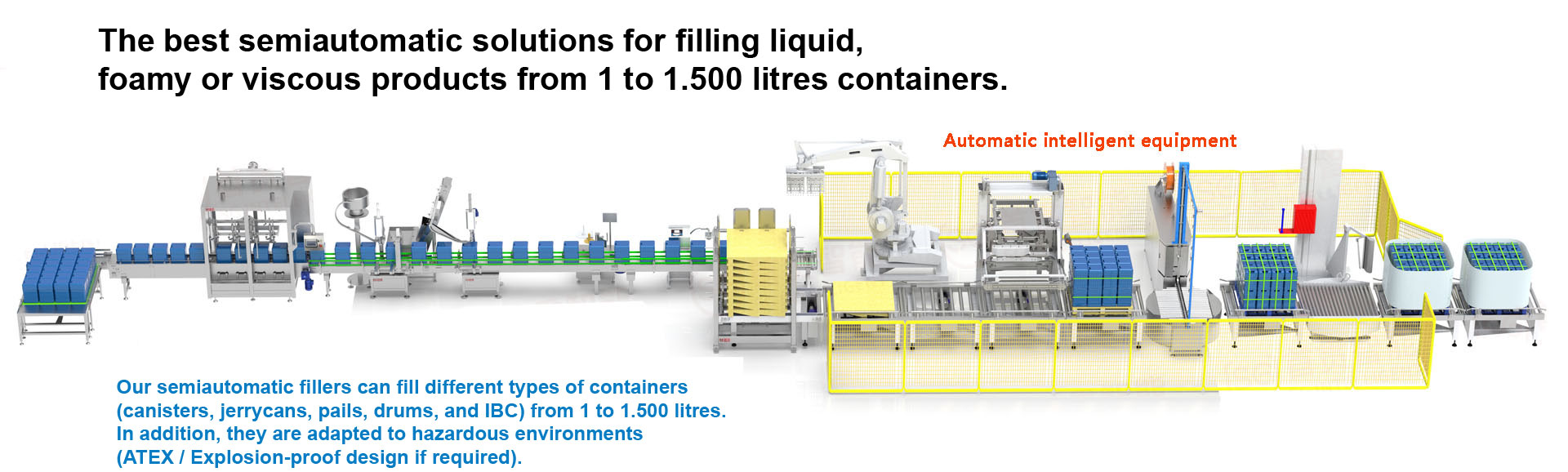

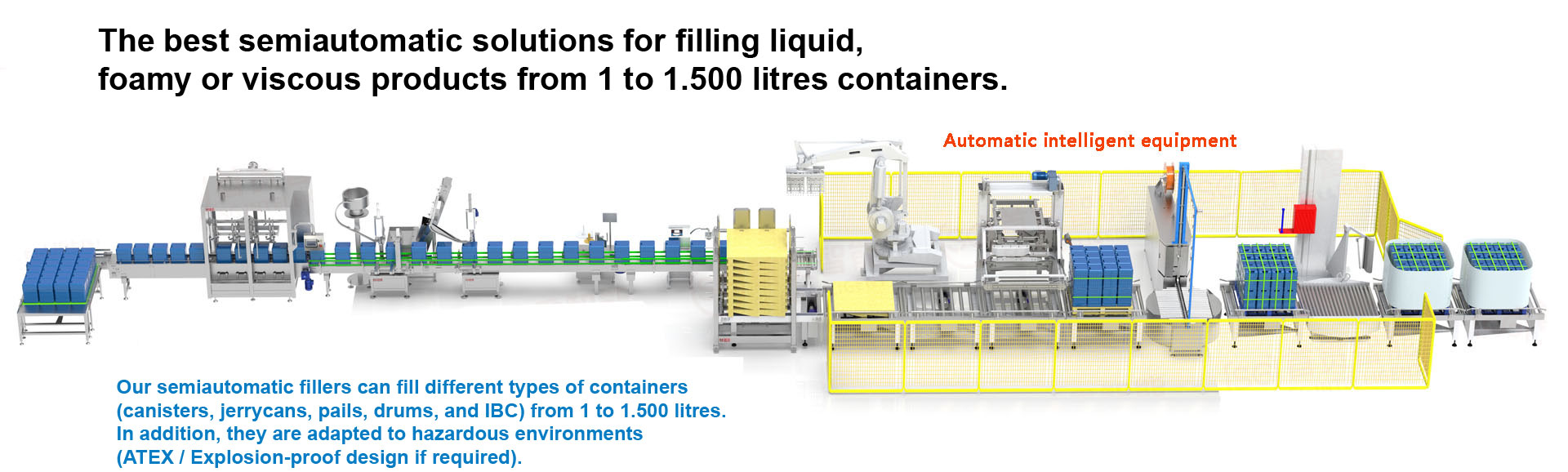

The Automatic Double-Head Liquid Pail Filling Machine is a high-efficiency, precision-engineered solution designed specifically for filling engine oil and other viscous liquids into pails (e.g., 18L, 20L, or custom sizes) with crown lid sealing. Featuring dual-head operation, this machine doubles productivity while ensuring accurate fill volumes, cleanliness, and secure crown lid application. It’s ideal for automotive lubricant manufacturers, oil refineries, and industrial packaging operations.

Key Features

Dual-Head Filling for High Throughput

Simultaneously fills two pails at once, doubling production speed compared to single-head machines.

Adjustable filling heads accommodate various pail sizes (e.g., 5L to 25L).

Precision Filling for Viscous Liquids

Volumetric or Gravimetric Filling: Ensures ±0.5% accuracy for engine oil and similar viscous products.

Variable Speed Control: Prevents splashing or foaming during filling.

Nozzle Design: Anti-clogging, self-venting nozzles for smooth dispensing of thick oils.

Integrated Crown Lid Sealing

Automatic Lid Placement: Picks and places crown lids onto filled pails.

Crown Sealing Mechanism: Compacts and seals lids securely, preventing leaks or contamination.

Optional Nitrogen Blanketing: Inert gas injection to preserve oil quality and extend shelf life.

Automation & Efficiency

PLC Touchscreen Interface: Easy programming for fill volumes, lid types, and production batches.

Conveyor Integration: Seamlessly connects with upstream (empty pail feeding) and downstream (labeling, palletizing) systems.

Batch Memory: Store settings for multiple products or pail sizes.

Safety & Cleanliness

Spill Prevention: Vacuum or pressure filling options to minimize drips and spills.

Drip Tray & Containment: Captures minor spills for easy cleanup.

ATEX Compliance (Optional): For hazardous environments where engine oil vapors may pose risks.

Customization Options

Material Compatibility: Stainless steel (304/316L) construction with optional PTFE coatings for compatibility with additives or aggressive oils.

Labeling/Coding: Integrated systems for batch numbers, expiration dates, or barcodes.

Remote Monitoring: IoT-enabled diagnostics for real-time performance tracking.

Technical Specifications

Filling Range: 5–25 liters per pail (adjustable in 0.1L increments).

Speed: Up to 600–1,200 pails/hour (depending on pail size and viscosity).

Accuracy: ±0.5% of target volume.

Power Requirements: 220V/50Hz or 110V/60Hz (customizable).

Lid Compatibility: Standard crown lids (diameter: 30–70mm, adjustable).

Safety Rating: IP65 (dust and water resistant).

Operation Steps

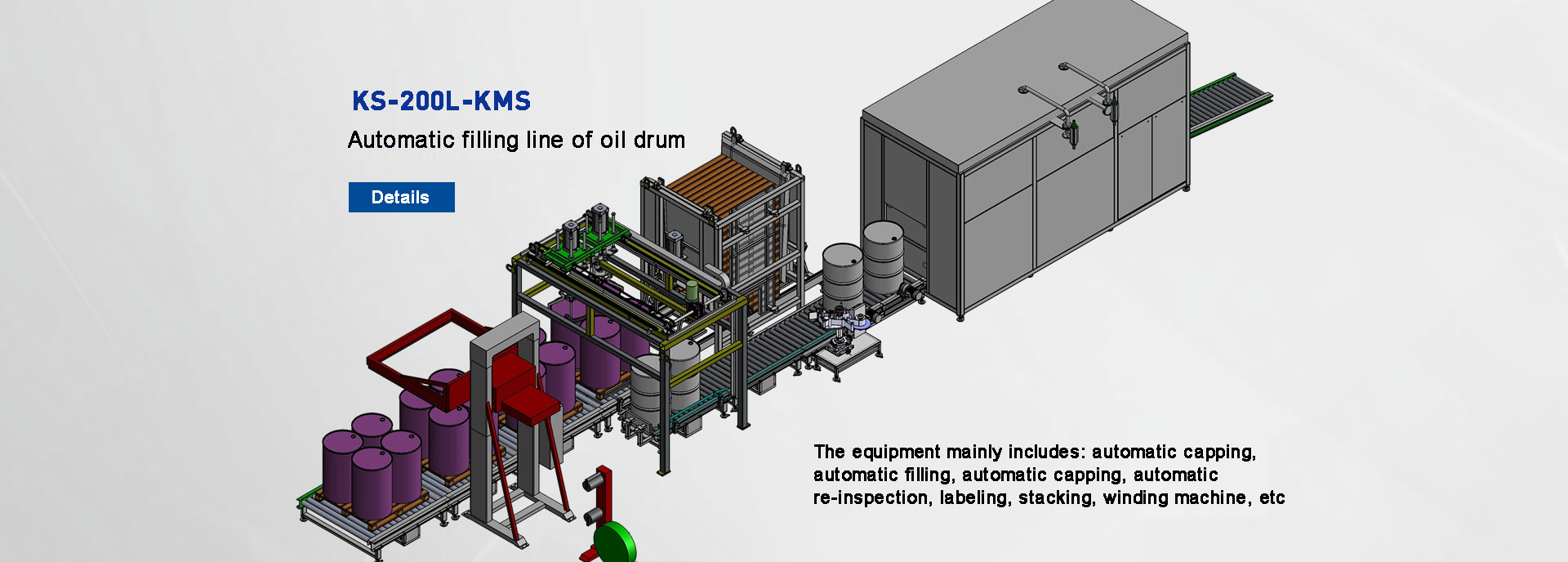

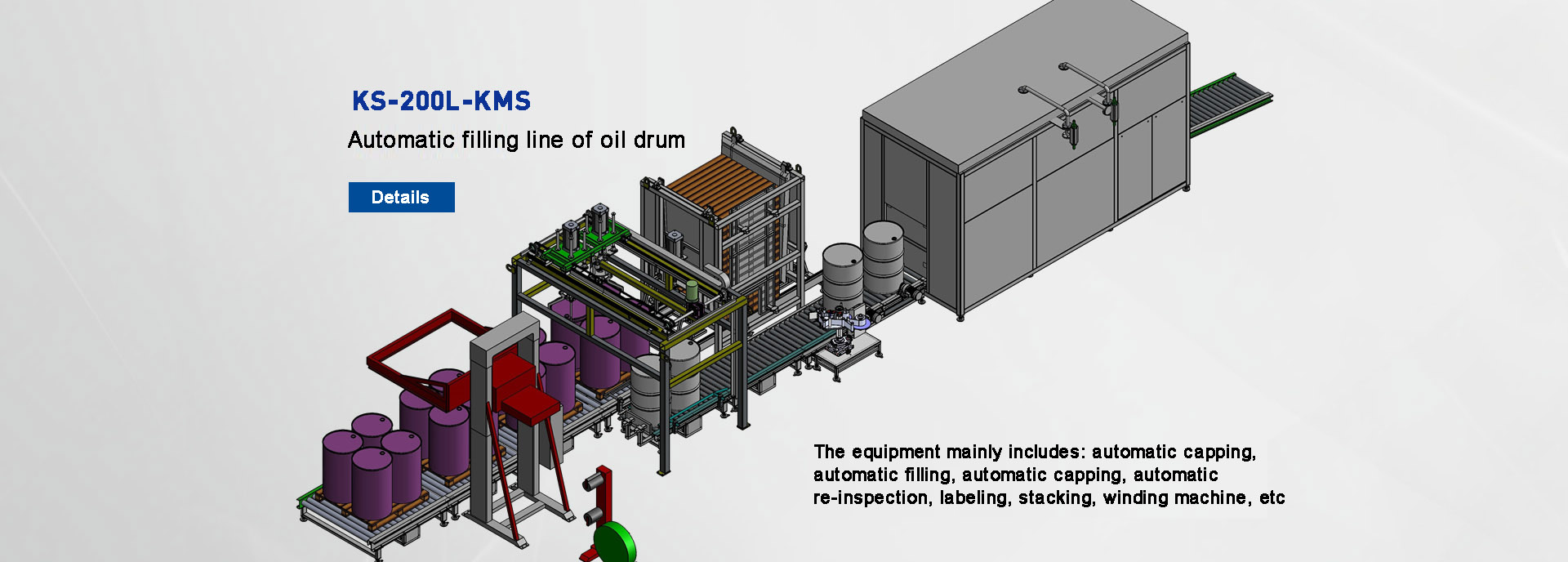

Empty Pail Feeding: Automated conveyor transports empty pails to the filling station.

Pre-Weighing (Optional): Checks pail weight before filling begins.

Filling: Dual heads dispense engine oil at controlled flow rates, monitored by load cells or flow meters.

Crown Lid Application:

Lid pickup mechanism retrieves a crown lid.

Sealing unit compresses and seals the lid onto the pail.

Post-Weighing (Optional): Verifies final weight for quality control.

Discharge: Filled and sealed pails move downstream for labeling, capping, or palletizing.

Applications

Engine Oils: Filling synthetic, semi-synthetic, or conventional motor oils.

Industrial Lubricants: Hydraulic oils, gear oils, and greases.

Greases & Thick Fluids: High-viscosity products requiring precise volumetric control.

Chemicals & Additives: Compatible with oil additives, solvents, or blended products.

Benefits

High Productivity: Dual-head design processes twice as many pails per minute.

Versatility: Handles multiple pail sizes and viscous liquids with customizable settings.

Leak-Proof Seals: Reliable crown lid sealing prevents contamination or evaporation.

Low Maintenance: Robust stainless steel construction with easy-clean components.

Scalability: Easily integrates with larger production lines for automated workflows.

Compliance: ATEX, CE, and ISO certifications ensure safety and quality standards.

Why Choose This Machine?

This Automatic Double-Head Pail Filling Machine is engineered for high-speed, precision filling of engine oil and viscous liquids, with integrated crown lid sealing for secure, leak-proof packaging. Its heavy-duty construction, advanced automation, and compliance with industry standards make it the ideal solution for automotive, industrial, and chemical manufacturing. Contact us for a customized quote or demo!

Immediate Order:

Website: http://m.360banjia.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Automatic Mouth-Finding Filling Machine Is Suitable for Ink Solvent/Polyurethane Filling[2025-05-13]

-

Cleaner Deodorant Bleach Chemical Liquid Filling Machine for Bottle[2025-06-06]

-

25 Liter Semi-Auto Paint Pail Filler with Safety Crown Lid[2025-05-29]

-

GZM-25 Weighing Filling Machine, a Filling Head with a Cap, Explosion-proof, Suitable for Chemical, Agriculture, Paint, Coating,[2025-04-28]