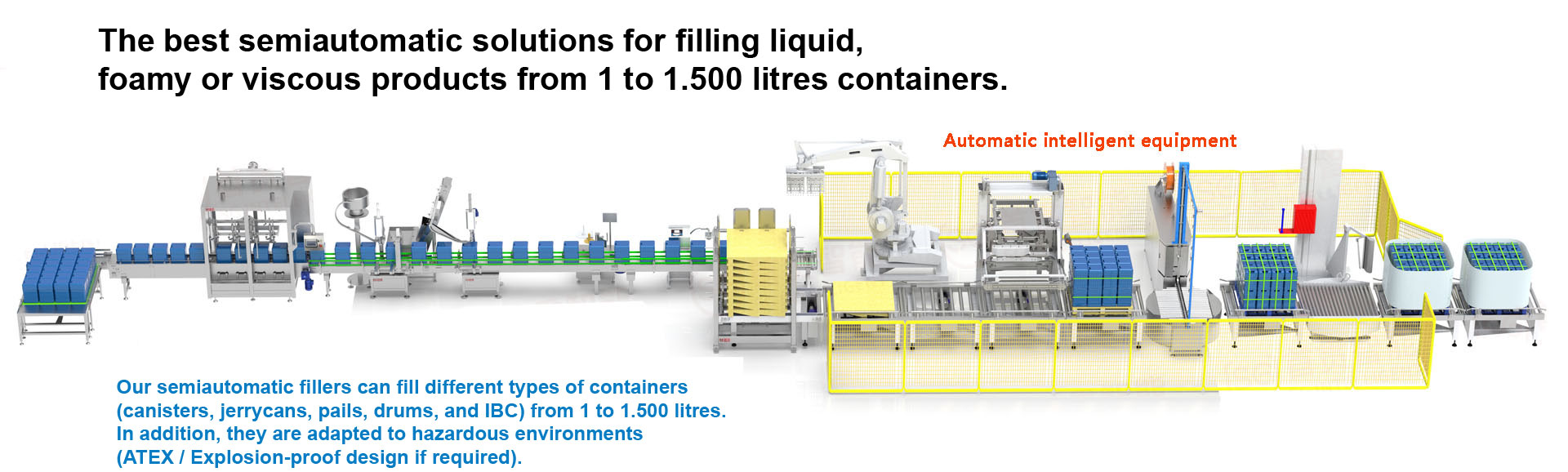

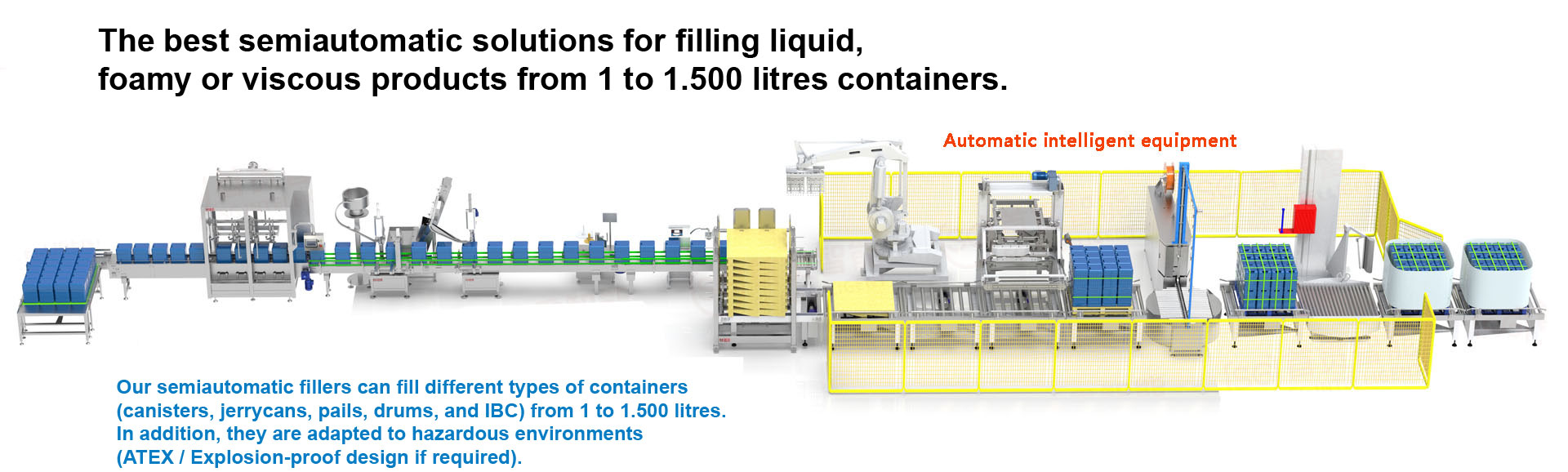

TriFill Pro TF-10000 Series

3-Head In-Line Net Weight Filler & Crimp Sealer with DFS SmartCart

60 Pails/Hour ? ±0.03% Accuracy ? 5-20L Capacity ? ATEX/FDA/GMP Ready

Technical Specifications

| Parameter | TF-1010 (Standard) | TF-1020X (ATEX) | TF-1030H (High-Visc) |

|---|

| Capacity | 5-20L (±0.03%) | 5-20L (±0.05%) | 5-20L (±0.04%) |

| Throughput | 60 Pails/Hour | 55 Pails/Hour | 50 Pails/Hour |

| Accuracy | ±0.03% Gravimetric | ±0.05% | ±0.04% |

| Viscosity Range | 50-500,000 cP | 100-300,000 cP | 5,000-1,000,000 cP |

| Filling Technology | Triple Coriolis Mass Flow | ATEX Gear Pumps | Heated Screw Auger |

| Crimp Force | 800-5000N (±0.8%) | 1000-6000N (±1%) | 1200-7000N (±0.9%) |

| Material Contact | 316L EP (Ra<0.4μm) | Hastelloy C276 | Ceramic-Coated Path |

| DFS SmartCart | 300L Capacity<br>? Auto-Height Docking<br>? RFID Tracking<br>? Predictive Replenishment | Same + ATEX Pressurization | Same + 80°C Heated Jacket |

| Changeover Time | <75s (Tool-Free) | <85s | <70s |

| Power | 480V/60Hz, 15kW | 24VDC Ex ia | 480V/60Hz, 18kW |

| Certifications | NTEP/OIML R117 Class 0.3 | ATEX Zone 1 | FDA 21 CFR 177.2600 |

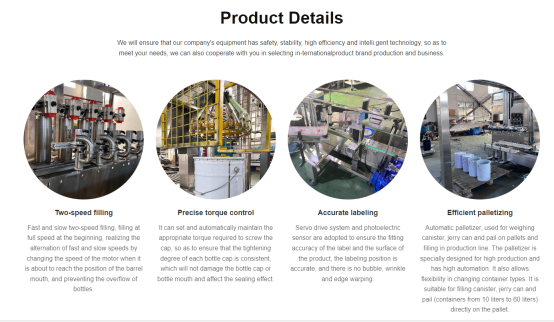

Core Innovations

1. TriSync? Triple-Head Precision

Performance Metrics:

| Metric | TF-1010 | Industry Standard |

|---|

| Fill Speed | 3.5L/sec/Head | 1.2L/sec/Head |

| Weight Variance | ±0.04% | ±0.15% |

| Calibration Drift | <0.003%/Year | 0.1%/Year |

2. DFS SmartCart? Intelligence

| Feature | Technology | Performance |

|---|

| Auto-Docking | LiDAR + Machine Vision | ±0.5mm Positioning |

| Material AI | Consumption Forecasting | <1% Stockout Risk |

| Collision Avoidance | 360° Ultrasonic Barrier | 0 Incident Guarantee |

Industry-Specific Engineering

Industrial Chemicals

| Feature | ATEX Solution |

|---|

| Vapor Containment | Nitrogen Blanketing (O?<0.3%) |

| Static Control | Ionized Air Curtain (10? ions/cm3) |

| Corrosion Resistance | Hastelloy C276 Path |

Edible Oils & Lubricants

Oxidation Prevention:

High-Viscosity Handling:

| Technology | Benefit |

|---|

| 80°C Path Heating | 1M cP Flow Capability |

| Shear Control | 0% Additive Degradation |

Pharmaceuticals

| Component | GMP Compliance |

|---|

| Cleanability | SIP Validation (121°C/30min) |

| Data Integrity | 21 CFR Part 11 + Audit Trail |

| Material Safety | USP Class VI Certification |

Operational Workflow

1. Pail Loading → 2. DFS Cart Auto-Docking →

3. Net Weight Taring (±0.01%) → 4. Triple-Head Filling (±0.03%) →

5. Vacuum Nozzle Retract → 6. AI-Guided Crimping (1000-6000N) →

7. Helium Leak Test (<10?? mbar·L/s) → 8. Blockchain Serialization

Cycle Time: 60 seconds/pail

Technical Advantages

Precision Engineering:

? Gravimetric Superiority:

- 0.001% Resolution Coriolis Meters

- Air Buoyancy Compensation

- Real-Time Density Correction

? DFS SmartCart Intelligence:

| **Feature**| **Performance**|

|----------------------|------------------------|

| 300L Capacity| 4×75L Totes |

| Auto-Height Docking | ±0.5mm (LiDAR Guided) |

| Material Tracking | RFID/NFC/QR Code|

? Industrial Durability:

- Tungsten Carbide Crimp Dies

- IP69K Washdown Protection

- 100,000-Hour MTBF

Certifications

? ATEX 2014/34/EU Zone 1 (TF-1020X)

? FDA 21 CFR 177.2600

? NTEP Certificate 20-041 (Class 0.3)

? ISO 9001:2015

? EHEDG EL Class I

Performance Validation

ExxonMobil Case Study:

*"After 6 months using TF-1010:

Why Choose TF-10000?

Triple-Head Efficiency:

? 60 Pails/Hour Throughput:

- 3× Coriolis Mass Flow Meters

- 0.8s/Pail Fill Time

- 99.5% Uptime

? Zero-Waste Ecosystem:

| **Technology**| **Residual** |

|-------------------------|---------------|

| Vacuum Suction | <0.05ml |

| Capillary Break| Zero Stringing |

| Overflow Protection| 0.1% Cutoff Accuracy |

? DFS SmartCart Benefits:

- 5-Minute Material Changeover

- Predictive Replenishment Alerts

- 300L Mobile Capacity

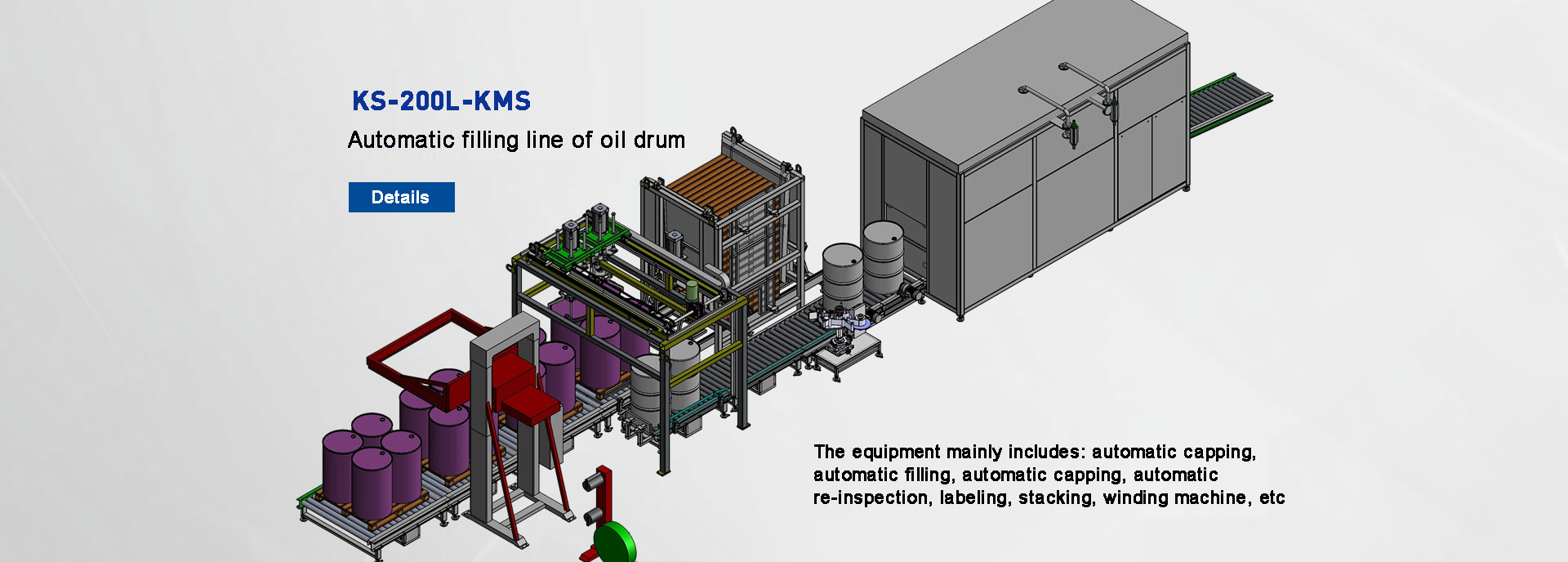

APPLICABLE BARREL TYPE

COMPANY PROFILE

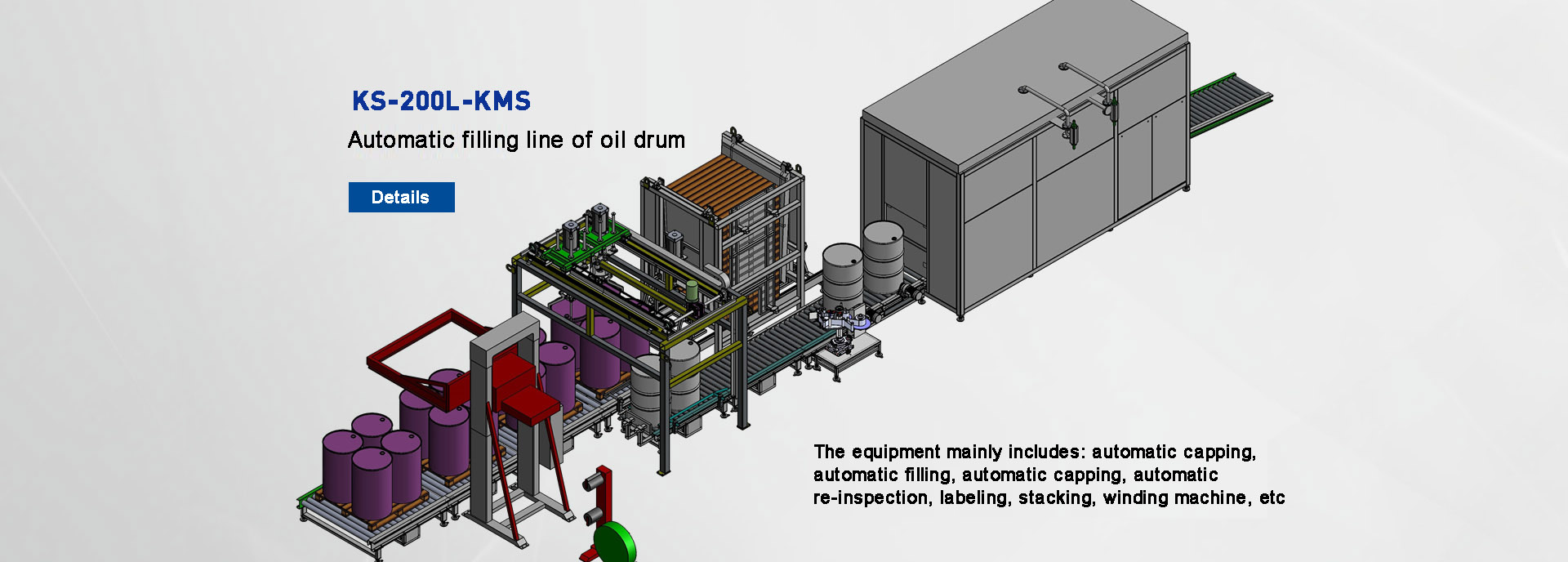

Shanghai Guangzhi Automation Equipment Co., Ltd. is a production and trading company specializing in the weighing industry. We are located in Shanghai, China's economic city, with convenient transportation and export ports all over the world. We cooperate with state-owned factories and international companies, and the quality is guaranteed.

We mainly focus on providing customers with weighing solutions, from commercial scales to industrial weighing machines. Such as pneumatic valve bag packaging machine, dry mix mortar bag packaging machine, cement packaging machine, natural stone powder packaging machine, flour powder packaging machine, wheat packaging machine, potato starch packaging machine, air packaging machine, granule bag packaging machine, grain packaging machine, fertilizer bag packaging machine, lubricant filling machine, 200 kg drum filling machine, 216L drum filling machine, 208L drum filling machine, ton barrel filling machine, IBC barrel filling machine, jumbo bag packaging machine, ton bag packaging machine, 30L pail filling machine, 50L pail asphalt filling machine, ATEX barrel filling machine, explosion-proof filling machine, etc.

Live Shooting

Support customization, low price, no middlemen, factory direct sales, large quantity and more favorable. Product quality assurance, simple operation and durability. We have professional customer service to consult and provide technical guidance at any time.

Our office and workshop

Consulting-Design-Procurement-Processing-Production-Installation-Debugging-Training-Maintenance